The Vital Role of AHU Air Handling Unit: Advancing Industries

- By:hqt

- 2024-06-19

- 29

Cleanrooms are specialized environments designed to maintain extremely low levels of airborne contaminants, crucial for industries such as pharmaceuticals, biotechnology, electronics manufacturing, and healthcare. These controlled spaces are essential for processes where even the smallest particle or microorganism can compromise product quality and safety. From sterile drug manufacturing to semiconductor fabrication, cleanrooms play a pivotal role in ensuring the integrity of products and processes.

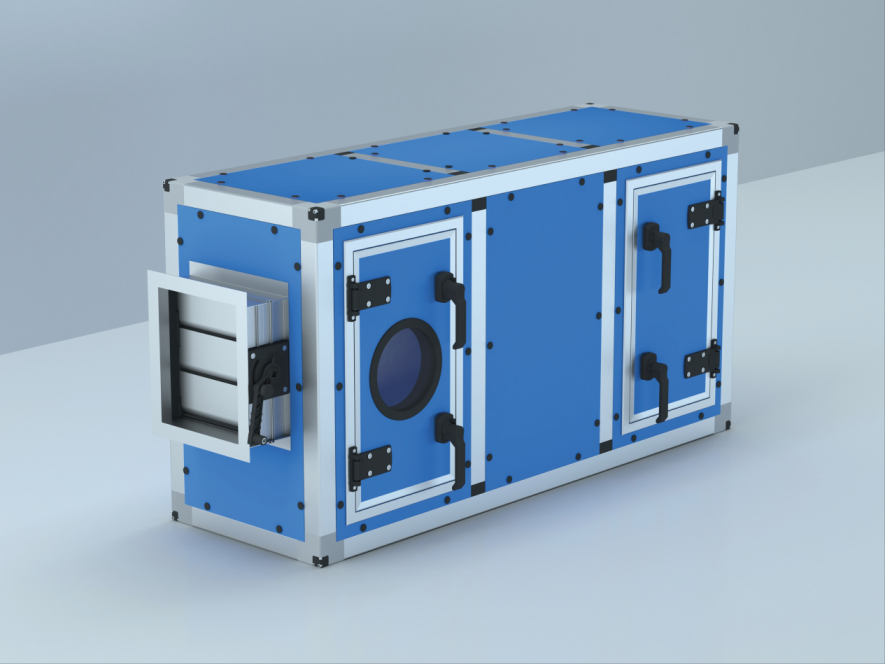

Understanding Air Handling Units (AHUs)

AHU Air Handling Unit is the backbone of cleanroom environments, responsible for managing air quality and environmental conditions. They perform a range of functions essential for maintaining cleanliness and controlling parameters such as temperature, humidity, airflow, and pressure.

Healthcare Industry

The healthcare industry relies heavily on cleanroom environments to safeguard patient health and ensure the efficacy of medical treatments. Within hospitals and clinics, AHU Air Handling Unit is indispensable for maintaining sterile conditions in operating theaters, laboratories, and isolation rooms. Let's delve into the specific needs and applications of AHUs in healthcare settings.

1. Patient Isolation Rooms: AHUs equipped with high-efficiency filtration systems are essential for preventing the spread of airborne pathogens in patient isolation rooms, reducing the risk of hospital-acquired infections, and protecting vulnerable patients.

2. Operating Theaters: In surgical environments, AHUs maintain precise temperature, humidity, and air quality levels to minimize the risk of surgical site infections and optimize patient outcomes. Reliable AHU systems are crucial for supporting aseptic surgical procedures and ensuring the safety of patients and medical staff.

3. Laboratories: Research laboratories require controlled environments to maintain the integrity of experiments and protect sensitive equipment. AHUs with advanced filtration capabilities help mitigate the risk of cross-contamination and ensure the accuracy and reliability of scientific data.

Pharmaceutical Industry

The pharmaceutical industry operates under strict regulatory guidelines to ensure the safety and efficacy of drug products. Cleanroom facilities are integral to pharmaceutical manufacturing processes, where AHUs play a vital role in maintaining controlled environments conducive to sterile production. Let's explore the unique challenges and requirements of AHUs in pharmaceutical settings.

1. Sterile Manufacturing: AHUs equipped with HEPA filters are essential for maintaining the cleanliness levels required for sterile drug manufacturing, preventing contamination, and ensuring product quality and safety.

2. Temperature and Humidity Control: Precise control of temperature and humidity is critical for pharmaceutical processes such as granulation, compression, and coating. AHUs with advanced control systems help maintain optimal conditions for drug manufacturing, reducing the risk of product variability and non-compliance.

3. Regulatory Compliance: Pharmaceutical cleanrooms must adhere to strict regulatory standards set forth by agencies such as the FDA and EMA. AHUs with comprehensive monitoring and validation capabilities aid in compliance efforts, providing documented evidence of environmental control measures.

Electronics Manufacturing Industry

In the electronics manufacturing industry, contamination control is essential to ensure the reliability and performance of electronic components and devices. Cleanroom environments free of dust, particulates, and static electricity are essential for semiconductor fabrication, microelectronics assembly, and other high-tech manufacturing processes. Let's examine the critical role of AHUs in electronics manufacturing facilities.

1. Particle Filtration: AHUs equipped with ultra-fine filters remove sub-micron particles from the air, preventing contamination of semiconductor wafers, electronic components, and sensitive equipment during manufacturing processes.

2. Static Control: Static electricity can cause damage to electronic components and disrupt manufacturing processes. AHU Air Handling Unit with ionization systems and anti-static measures helps mitigate the risk of electrostatic discharge in cleanroom environments, ensuring product quality and yield.

3. Temperature and Humidity Stability: Consistent control of temperature and humidity is essential for the production of electronic devices with precise specifications. AHUs with temperature and humidity sensors maintain stable environmental conditions, minimizing the risk of material defects and production delays.

Primary Functions of AHUs:

Air Filtration: AHUs employ advanced filtration systems, including HEPA filters, to remove particles and contaminants from incoming air, ensuring that only clean air enters the cleanroom environment.

1. Temperature and Humidity Control: AHUs regulate temperature and humidity levels within the cleanroom to ensure they remain within specified ranges, crucial for maintaining process integrity and personnel comfort.

2. Airflow Management: AHUs control the direction, velocity, and distribution of air within the cleanroom, preventing the accumulation and spread of contaminants while maintaining uniform environmental conditions.

3. Pressurization: AHUs maintain positive or negative pressure differentials as per cleanroom classification requirements, preventing the ingress of contaminants or containing any potential contamination within the cleanroom space.

4. Monitoring and Control: Modern AHUs are equipped with sensors and control systems that continuously monitor environmental parameters, allowing for real-time adjustments to ensure compliance with regulatory standards and industry guidelines.

Importance of AHUs in Cleanrooms

The role of AHUs in cleanrooms cannot be overstated. They are fundamental to maintaining the cleanliness and integrity of these controlled environments, ensuring that critical processes remain unaffected by contaminants.

1. Removing Contaminants: AHU Air Handling Unit effectively removes particles, microorganisms, and other contaminants from the air, minimizing the risk of contamination and ensuring the quality and safety of products manufactured within the cleanroom.

2. Regulating Environmental Conditions: AHUs play a crucial role in controlling temperature, humidity, and airflow, creating an environment conducive to sensitive manufacturing processes and research activities.

3. Ensuring Compliance: AHUs help cleanroom facilities meet stringent regulatory requirements and industry standards by maintaining specified cleanliness levels and environmental conditions.

Components of AHUs

AHUs consist of various components, each serving a specific function in the operation of the unit. Understanding these components is essential for designing, installing, and maintaining efficient AHU systems.

1. Filters: HEPA filters are the primary components responsible for removing airborne particles and contaminants. Pre-filters and other filtration media may also be used to extend the lifespan of HEPA filters.

2. Fans: Fans circulate air through the AHU Air Handling Unit system, ensuring adequate airflow and distribution within the cleanroom environment.

3. Coils: Heating and cooling coils regulate the temperature of the air passing through the AHU, maintaining the desired thermal conditions within the cleanroom.

4. Dampers: Dampers control the flow of air within the AHU Air Handling Unit system, allowing for precise adjustments to airflow rates and distribution.

5. Sensors: Sensors monitor environmental parameters such as temperature, humidity, pressure, and particle counts, providing real-time data for system control and optimization.

6. Control Systems: Control systems coordinate the operation of AHU Air Handling Unit components based on input from sensors and user-defined setpoints, ensuring optimal performance and compliance with cleanroom requirements.

Design Considerations and Best Practices

Designing and operating AHUs in cleanroom facilities requires careful consideration of various factors to ensure optimal performance, energy efficiency, and regulatory compliance.

1. Air Change Rates: Determining the appropriate air change rate is essential for maintaining cleanliness levels while minimizing energy consumption and operational costs.

2. Filter Selection and Maintenance: Selecting the right filters and implementing a proactive maintenance program are critical for ensuring efficient operation and extending the lifespan of AHU components.

3. Energy Efficiency: Implementing energy-efficient AHU Air Handling Unit systems can lead to significant cost savings while reducing environmental impact. Strategies such as variable air volume (VAV) control and heat recovery can help optimize energy usage.

4. Noise Control: Minimizing noise generated by AHUs is important for maintaining a comfortable and productive working environment within the cleanroom facility.

5. Compliance with Standards: AHU systems must comply with relevant regulatory standards and industry guidelines, ensuring that cleanroom environments meet the required cleanliness levels and operational parameters.

Case Studies and Examples

Real-world examples highlight the effectiveness of AHUs in enhancing cleanroom performance and productivity across various industries.

1. Case Study 1: Pharmaceutical Manufacturing E-ZONG's AHU Air Handling Unit systems were instrumental in helping a pharmaceutical company achieve compliance with stringent regulatory requirements while improving manufacturing efficiency and product quality.

2. Case Study 2: Semiconductor Fabrication A semiconductor manufacturer implemented E-ZONG's AHU Air Handling Unit solutions to maintain ultra-clean environments required for semiconductor fabrication, resulting in higher yields and reduced contamination-related defects.

3. Case Study 3: Hospital Operating Theatres E-ZONG's AHU units are widely used in hospital operating theatres to maintain sterile conditions during surgical procedures, minimizing the risk of infections and ensuring patient safety.

Conclusion

AHUs are essential components of cleanroom environments, playing a critical role in maintaining cleanliness, controlling environmental conditions, and ensuring compliance with regulatory standards. By understanding the functions, components, and best practices associated with AHU Air Handling Unit, cleanroom facilities can optimize performance, enhance productivity, and safeguard the integrity of their processes and products. E-ZONG's expertise in AHU manufacturing and design makes them a trusted partner for cleanroom solutions across industries.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution -

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow -

The Sleek and Efficient Linear Slot Diffuser for Air Vent

The Sleek and Efficient Linear Slot Diffuser for Air Vent -

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors -

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door -

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency -

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces -

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent -

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions -

Elegant & Durable: Premium Swing Door Protection for Hospitals

Elegant & Durable: Premium Swing Door Protection for Hospitals

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind