Best AHU Aluminum Thermal Break Profile for Air Handling Units

- By:hqt

- 2024-09-12

- 29

Introduction to AHU Aluminum Profiles

Definition and Purpose

AHU Aluminum Thermal Break Profiles, categorized as specialized extrusions, are meticulously engineered for integration into the framework, casing, and support structures of air handling units (AHUs). The overall architectural framework of AHUs, which are pivotal in heating, ventilation, and air conditioning (HVAC) systems, is significantly enhanced by these profiles. Essential internal components such as fans, filters, and coils are accommodated by these profiles, which play a crucial role in ensuring their optimal performance and extended service life.

Material Benefits

Constructed from high-quality aluminum alloys, AHU aluminum profiles are distinguished by their exceptional blend of strength, load-bearing capacity, and resistance to environmental degradation. The choice of aluminum as a material for HVAC applications is validated by its lightweight yet robust nature, facilitating easier handling and installation while providing sufficient strength to support the unit's components effectively. Additionally, the inherent corrosion resistance of aluminum ensures the profiles remain durable and reliable even in harsh operational environments.

Structural Advantages of Aluminum Profiles

Strength and Load-Bearing Capacity

Engineered with meticulous attention to structural design, AHU Aluminum Thermal Break Profile offers outstanding strength and load-bearing capacity. The internal elements of the AHU, including substantial components like fans, filters, and coils, are supported by these profiles, which are subjected to considerable operational stresses. Uniform load distribution is ensured by the profiles, maintaining the stability and alignment of these components, which is critical for the efficient functioning and longevity of the AHU.

Corrosion Resistance

The inherent corrosion resistance of aluminum is a standout advantage, contrasting sharply with materials like steel, which are prone to rust and deterioration over time. A protective oxide layer that shields aluminum from environmental damage is developed naturally. This characteristic is particularly beneficial for AHU applications, where exposure to moisture and fluctuating temperatures could otherwise lead to rapid material degradation. Consequently, minimal maintenance is required for AHU aluminum profiles, which offer an extended service life.

Customization and Design Flexibility

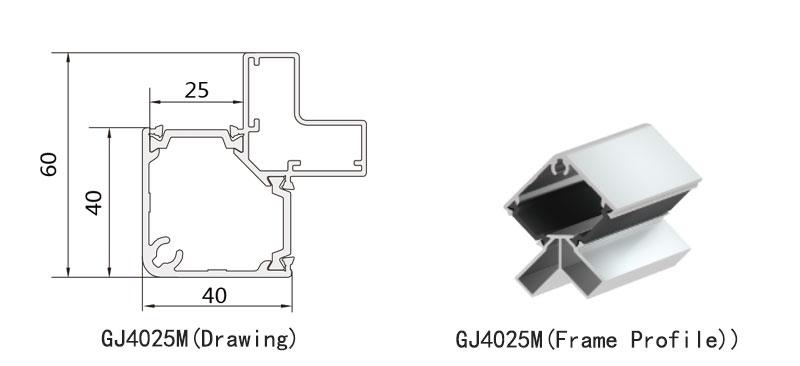

Customizable Profiles

Adaptability is a defining feature of AHU Aluminum Thermal Break Profile. These profiles can be precisely machined and customized to align with specific design requirements and application needs. Tailoring in terms of dimensions, shapes, and other specifications allows aluminum profiles to fit both standard AHUs and bespoke systems. This flexibility ensures the profiles can meet various design criteria and integrate seamlessly into diverse HVAC systems.

Integral Features

Integral features such as grooves and slots are frequently included in aluminum profiles, facilitating the straightforward attachment of components and accessories. Enhanced versatility is achieved through these built-in features, allowing for the easy integration of additional elements like mounting brackets and connectors. Streamlined assembly and the ability to make prompt modifications and upgrades are enabled by this design approach.

Surface Treatments and Finishes

Powder Coating

Powder coating is a commonly employed surface treatment that enhances both the durability and visual appeal of the AHU Aluminum Thermal Break Profile. Involving the application of a dry powder to the aluminum, which is then cured under heat to form a robust, protective coating, this process improves resistance to environmental factors such as UV radiation, moisture, and chemicals. The profiles' lifespan is extended, and their aesthetic appearance is preserved over time.

Anodizing

Anodizing, another prevalent surface treatment, involves creating an oxide layer on the aluminum surface, thereby increasing resistance to wear and corrosion. This process also enhances the visual appeal of the profiles, offering a variety of colors and finishes to suit different design preferences. An additional shield against environmental damage is provided by the anodized layer, ensuring that the profiles remain in excellent condition throughout their service life.

Common Features and Specifications

Material Type

When aluminum is compared to other materials like steel, several distinct advantages become evident. The significantly lighter weight of aluminum reduces the overall weight of the AHU structure, simplifying transportation and installation. Additionally, aluminum's superior corrosion resistance means extensive maintenance or protective coatings are not required, unlike steel, which is susceptible to rust and deterioration over time.

Thickness and Shape

A range of thicknesses and shapes is available for AHU aluminum profiles to accommodate different structural requirements and applications. The specific demands of the AHU and HVAC system determine the choice of thickness and profile shape. Enhanced strength and support are provided by thicker profiles, while varying shapes can be selected to optimize spatial efficiency and structural performance.

Size Variability

An extensive array of sizes is available for aluminum profiles, catering to various AHU designs and HVAC system specifications. This size variability ensures that profiles can be chosen to fit specific design criteria and support AHU components effectively. The ability to select the appropriate profile size is crucial for achieving optimal performance and reliability, whether for compact units or larger systems.

Selecting the Right AHU Aluminum Profile

Strength and Durability

Careful consideration of both strength and durability is required when selecting the appropriate AHU aluminum profile. The alignment of the profile's thickness and shape with the load requirements and operational stresses anticipated in the AHU is essential. Insufficient strength in a profile could compromise the stability of the AHU components, whereas an overly robust profile may incur unnecessary costs. Balancing these factors is crucial for ensuring optimal performance and cost-efficiency.

Application-Specific Needs

Unique requirements of various HVAC systems and building designs may influence the choice of aluminum profiles. Factors such as AHU size, internal component types, and environmental conditions need to be taken into account. By thoroughly evaluating these application-specific needs, the most suitable aluminum profile can be selected to ensure efficient and reliable AHU operation.

Conclusion

Critical to both the construction and effective functioning of air handling units, AHU aluminum thermal break profile combines exceptional strength, corrosion resistance, and design flexibility. Tailored solutions are facilitated by the ability to customize profiles with different shapes, sizes, and finishes, meeting specific project needs. The profiles' durability and visual appeal are further enhanced by surface treatments such as powder coating and anodizing. The selection of the right aluminum profile significantly impacts the AHU's performance and longevity. As a leading supplier, E-ZONG offers a diverse range of high-quality AHU aluminum profiles designed to meet various requirements and ensure optimal performance across different HVAC systems.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution -

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow -

The Sleek and Efficient Linear Slot Diffuser for Air Vent

The Sleek and Efficient Linear Slot Diffuser for Air Vent -

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors -

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door -

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency -

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces -

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent -

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions -

Elegant & Durable: Premium Swing Door Protection for Hospitals

Elegant & Durable: Premium Swing Door Protection for Hospitals

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind