How Do Air Handling Units Ensure Sterility in Your Industrial Environments?

- By:hqt

- 2024-06-21

- 29

Discover how air handling units (AHUs) revolutionize diverse industries by maintaining sterility, preserving product purity, safeguarding quality, ensuring elegance, guarding against defects, and enhancing process control. Explore AHU functions for medical facilities, bio-pharmaceuticals, food processing, cosmetics, machinery/electronics, and general manufacturing, ensuring regulatory compliance and optimal performance.

Ensuring Sterility in Medical and Health Facilities

1.1 Ultra-Clean Air for Patient Safety

In medical and health facilities, maintaining sterility is paramount to safeguard patient health and prevent infections during surgeries and procedures. Air Handling Units (AHUs) equipped with High Efficiency Particulate Air (HEPA) filters play a crucial role in achieving ultra-clean air environments.

1.2 HEPA Filtration: Removing Airborne Pathogens

HEPA filters are designed to capture particles as small as 0.3 microns with high efficiency, including bacteria, viruses, and other airborne contaminants. By incorporating HEPA filters into AHUs, medical facilities can effectively remove pathogens from the air, ensuring that operating rooms and patient care areas meet stringent cleanliness standards set by regulatory bodies such as the Centers for Disease Control and Prevention (CDC) and the World Health Organization (WHO).

1.3 Stringent Cleanliness Standards

Regulatory bodies impose strict cleanliness standards on medical facilities to minimize the risk of infections and ensure patient safety. AHUs equipped with HEPA filters help medical facilities adhere to these standards by continuously circulating and filtering the air to maintain a sterile environment. This is particularly crucial in environments where patients may have compromised immune systems, such as intensive care units and isolation wards.

Preserving Product Purity in Bio-pharmaceuticals

2.1 Controlled Environments for Biologics Manufacturing

Bio-pharmaceutical manufacturing requires controlled environments to prevent contamination and ensure the efficacy of delicate biologics and drugs. AHUs play a vital role in preserving product purity by providing precise control over temperature, humidity, and air pressure.

2.2 Advanced Filtration Systems for Product Integrity

In addition to temperature and humidity control, AHUs in bio-pharmaceutical facilities are equipped with advanced filtration systems to eliminate particulate matter and microbial contaminants. This ensures product integrity and compliance with regulatory requirements from organizations such as the Food and Drug Administration (FDA) and the European Medicines Agency (EMA).

2.3 Compliance with Regulatory Requirements

Regulatory compliance is essential in the bio-pharmaceutical industry to ensure the safety and efficacy of drugs and biologics. AHUs equipped with HEPA filters and advanced filtration systems help bio-pharmaceutical manufacturers meet regulatory requirements by maintaining controlled environments that minimize the risk of contamination and product spoilage.

Safeguarding Quality in Food and Beverage Processing

3.1 Hygienic Environments for Food Safety

Food processing facilities require hygienic environments to prevent microbial contamination and ensure the safety and quality of consumables. AHUs with antimicrobial filters play a crucial role in safeguarding food quality by maintaining clean air in production areas.

3.2 Temperature and Humidity Control for Microbial Inhibition

In addition to filtration, AHUs control temperature and humidity levels to inhibit microbial growth in food processing facilities. This is essential for preventing foodborne illnesses and meeting stringent regulatory standards such as Hazard Analysis and Critical Control Points (HACCP).

3.3 Meeting Regulatory Standards

Regulatory agencies impose strict standards on food processing facilities to ensure the safety and quality of food products. AHUs equipped with antimicrobial filters and precise temperature and humidity control help food manufacturers meet these standards by creating hygienic environments that minimize the risk of contamination and ensure product safety.

Ensuring Purity and Elegance in Cosmetics Manufacturing

4.1 Pristine Environments for Product Integrity

Cosmetics manufacturing demands pristine environments to prevent contamination and preserve the purity and aesthetic appeal of products. AHUs tailored for cosmetic production play a vital role in ensuring product integrity by removing airborne particles with HEPA filtration.

4.2 Consistent Product Quality

In addition to filtration, AHUs provide precise control over air quality and airflow rates to ensure consistent product quality in cosmetics manufacturing. This is essential for meeting the expectations of discerning consumers and regulatory authorities alike.

4.3 Regulatory Compliance

Regulatory compliance is essential in the cosmetics industry to ensure product safety and quality. AHUs equipped with HEPA filtration and precise air quality control help cosmetic manufacturers meet regulatory requirements by maintaining cleanroom environments that minimize the risk of contamination and ensure product purity.

Guarding Against Defects in Machinery and Electronics Industries

5.1 Dust-Free Environments for Product Reliability

The machinery and electronics industries require dust-free environments to prevent defects in sensitive components and ensure product reliability. AHUs with advanced filtration systems play a crucial role in guarding against defects by eliminating particulate matter from the air.

5.2 Temperature and Humidity Control for Manufacturing Processes

In addition to filtration, AHUs control temperature and humidity levels in manufacturing facilities to ensure optimal conditions for semiconductor fabrication and electronic assembly. This is essential for maintaining high yields and product quality in the machinery and electronics industries.

5.3 Enhancing Product Quality

By providing dust-free environments and precise control over temperature and humidity, AHUs enhance product quality in the machinery and electronics industries. This helps manufacturers meet customer expectations and regulatory requirements while minimizing the risk of defects and ensuring product reliability.

Enhancing Process Control in General Manufacturing

6.1 Customizable Solutions for Diverse Industries

Various manufacturing processes across industries benefit from cleanroom environments to maintain product quality and reliability. AHU manufacturers like E-ZONG offer customizable solutions tailored to meet the specific cleanliness requirements of diverse manufacturing operations.

6.2 Optimal Process Control

Customizable AHUs enhance process control in general manufacturing by providing cleanroom environments that minimize contamination and ensure product quality. This is essential for meeting industry standards and regulatory requirements while optimizing manufacturing processes for efficiency and reliability.

6.3 Continuous Improvement

E-ZONG and other AHU manufacturers are committed to continuous improvement and innovation to meet the evolving needs of the manufacturing industry. By developing advanced filtration systems and control technologies, AHU manufacturers help manufacturers across industries enhance process control and achieve greater levels of productivity and quality.

Conclusion

In conclusion, air handling units (AHUs) serve as indispensable components across various industries, ensuring critical functions like sterility maintenance, product purity preservation, and quality safeguarding. From medical facilities to food processing plants, AHUs play a vital role in upholding regulatory standards, enhancing product reliability, and optimizing manufacturing processes. As technology advances, AHU manufacturers continue to innovate, offering customizable solutions tailored to meet the evolving needs of diverse sectors. In essence, AHUs stand as integral elements in ensuring air quality, cleanliness, and operational efficiency across a wide range of applications.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

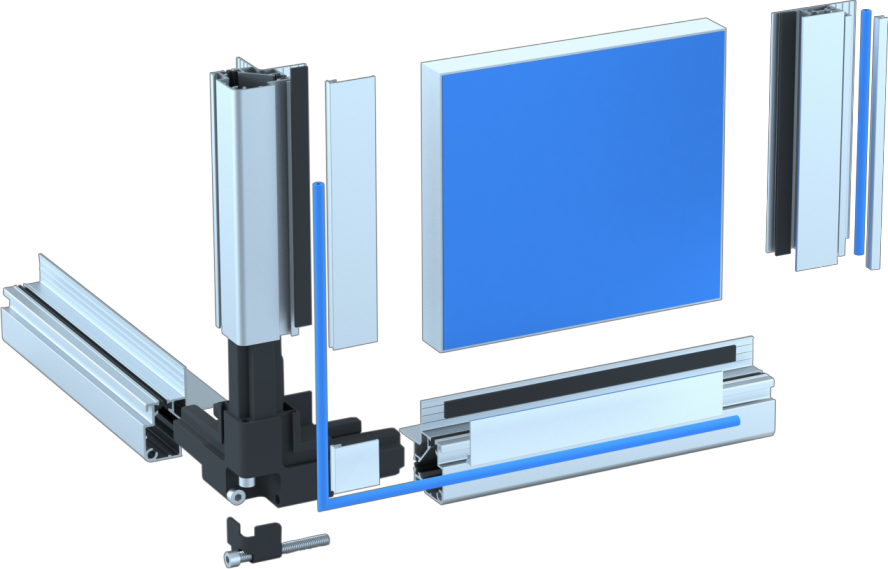

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution -

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow -

The Sleek and Efficient Linear Slot Diffuser for Air Vent

The Sleek and Efficient Linear Slot Diffuser for Air Vent -

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors -

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door -

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency -

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces -

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent -

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions -

Elegant & Durable: Premium Swing Door Protection for Hospitals

Elegant & Durable: Premium Swing Door Protection for Hospitals

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind