Must-Have To Hospitals: Clean Room Door Hall Isolation Room

- By:hqt

- 2022-11-17

- 29

What Is The Aluminum For Clean Room Process Equipment?

What is the Clean Room Process Equipment?

A clean room is a controlled environment that has been designed to limit the number of contaminants and ensure that the air quality is appropriate for a given user. The purpose of a clean room is to protect sensitive equipment or products, such as semiconductors or pharmaceutical drugs, from contamination. The primary concern in clean rooms is contamination by airborne particles, including bacteria, viruses, and fungi.

Clean rooms are often used in hospitals and laboratories where there may be a risk of infection from microorganisms. They can also be found in factories where sensitive products are being manufactured or packaged.

The Aluminum For Clean Room Process Equipment:

Aluminum is one of the most widely used metals in the world. It is the most common metal found in the Earth's crust, and it is an excellent conductor of heat and electricity. Aluminum is lightweight, strong, and corrosion-resistant. Its combination of properties makes it ideal for use in clean room process equipment.

Aluminum for Clean Room Process Equipment is an important part of any industry where cleanliness is needed. This includes medical and pharmaceutical industries, food processing plants, and other commercial facilities that have strict standards when it comes to maintaining cleanliness.

Why Use Aluminum For Clean Room Process Equipment?

Why use aluminum for Clean Room Process Equipment? What are the benefits of using aluminum for Clean Room Process Equipment?

Before that, we need to understand what the characteristics of Clean Room Process Equipment are to know what material is suitable. Simply put, it needs to be durable, corrosion-resistant, flexible, and easy to clean.

Durable and easily machined:

Aluminum is a light and durable metal that is well-suited for use in Clean Rooms. It has high corrosion resistance, can be easily machined and formed, and will not corrode or rust when exposed to the environment. Aluminum is also widely available, which makes it an affordable choice for building clean rooms.

Low thermal conductivity:

Aluminum has a low thermal conductivity when compared to other metals like copper and steel. This means that aluminum will not transfer heat as quickly as those other metals. This helps keep the temperature inside your clean room stable and reduces the need for additional heating or cooling systems, which can save you money on energy costs over time.

Fearless to water:

Aluminum is a good choice for use in clean rooms because it does not corrode or rust when exposed to water vapor or humidity. If you choose aluminum for your Clean Room process equipment items like doors and windows, they will last longer. They last longer than similar products made from other materials such as stainless steel or galvanized steel.

More flexible:

Aluminum is also more flexible than other metals like copper so it can be easily bent into different shapes without breaking or cracking over time. This makes it easy to build doors and windows that fit exactly where they're needed inside your facility so there's no wasted space between them and their frame.

What's more, aluminum does not corrode like other metals do, which makes it easy to clean and maintain. So this kind of aluminum is very suitable for Clean Room. E-ZONG from China, with nearly 30 years of production experience, can provide you with high-quality aluminum for Clean Room Process Equipment.

The Surface Treatment Of The E-ZONG Aluminum For Clean Room Process Equipment:

E-ZONG provides customers with high-quality surface-treated aluminum. According to different surface treatment processes, E-ZONG's clean room aluminum profiles are divided into anodized (light-colored) aluminum profiles, electrophoretic aluminum profiles, spray-coated aluminum profiles, and grinding aluminum profiles.

Here are the benefits of these different surface treatment processes:

Anodized (light-colored) aluminum profiles:

The anodizing process has excellent corrosion resistance and is also able to withstand high temperatures. Anodized aluminum is a good choice for corrosive environments or for use in areas where there is exposure to high heat or moisture. It also offers excellent resistance to atmospheric conditions such as ultraviolet light and sulfuric acid mist or fume.

Electrophoretic aluminum profiles:

Electrophoretic coating is a type of paint-coating process that uses electrostatic attraction to deposit paint on a substrate. The result is an extremely smooth and uniform surface with excellent corrosion resistance. This type of coating is ideal for use in clean rooms due to its ability to resist contamination from particles or liquids.

Spray-coated aluminum profiles:

Spray coatings can be used as an alternative to anodizing or electrophoretic coating due to their low cost and ease of application. They are also used on parts where it is difficult to achieve uniform coloration (such as complex shapes). Spray coatings can be applied using a variety of materials including water-based paints and powder coatings which offer better corrosion resistance than liquid paints.

Grinding aluminum profile:

The grinding process is used to make clean room doors and windows. The surface of the material is very smooth after grinding processing, which makes it easy to clean up dust or dirt when cleaning rooms. In addition, it can also make the surface of the material more resistant to corrosion caused by dust particles.

In E-ZONG, you can choose the surface treatment technology of aluminum according to your own needs. If you want a more professional solution, E-ZONG will also help you make a more perfect solution. Because it has made perfect solutions for Clean Rooms such as many hospitals and laboratories. These can all be viewed on their official website.

Conclusion:

Besides, E-ZONG's aluminum material is 3m or 6m per piece (they also accept ODM and OEM service). E-ZONG guarantees that the surface color of aluminum is stable for 10-20 years indoors. In addition, their aluminum has further processing steps such as CNC milling, drilling, welding, etc.

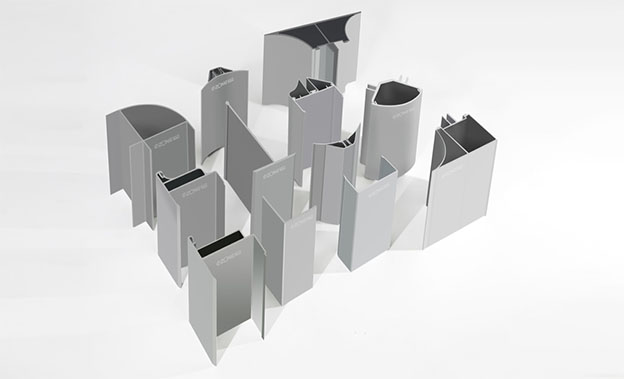

What's more, at E-ZONG you can find any aluminum shape you need. For example, common types: are slotted aluminum profiles, angle aluminum profiles, outer arc column aluminum profiles, T-beams, etc. Moreover, E-ZONG also has aluminum profiles specially developed for some new materials.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution -

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow -

The Sleek and Efficient Linear Slot Diffuser for Air Vent

The Sleek and Efficient Linear Slot Diffuser for Air Vent -

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors -

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door -

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency -

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces -

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent -

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions -

Elegant & Durable: Premium Swing Door Protection for Hospitals

Elegant & Durable: Premium Swing Door Protection for Hospitals

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind