Why Opt Aluminum Profiles For Air Handling Units: Custom Service

- By:hqt

- 2024-10-20

- 29

The material selection in air handling unit (AHU) design is crucial, as it significantly impacts the system's efficiency, longevity, and overall functionality. Aluminum has emerged as one of the leading materials utilized in the construction of these units. But what sets it apart? The unique properties of aluminum profiles confer several advantages over alternative materials, rendering them the preferred choice in HVAC applications.

At the outset, the inherent lightness of aluminum, coupled with its considerable strength, makes it an optimal solution for air handling systems that demand robust support frameworks while simultaneously avoiding the addition of unnecessary weight to the system’s structure. This property also contributes to streamlined installation processes, enhancing operational efficiency, minimizing labor expenditure, and reducing the likelihood of assembly errors.

A further critical attribute of aluminum profiles is their exceptional resistance to corrosion. Air handling units frequently operate under varying temperature and humidity conditions, necessitating materials that can withstand these challenges. Aluminum’s natural oxidation layer acts as a protective barrier against rust, ensuring the integrity of the AHU framework over time, even in harsh environments.

Moreover, the versatility of aluminum allows for seamless customization and integration of various components. Whether the design necessitates intricate geometries or incorporates slots for attaching additional accessories, aluminum profiles can be manufactured to conform to specific design parameters, thus making them highly adaptable for both standard and bespoke AHU configurations.

Aluminum or Steel: Which Material Suits Air Handling Units Best?

A common deliberation during AHU design involves choosing between aluminum and steel profiles for the unit’s framework. While each material boasts its own set of strengths, a deeper understanding of their respective properties can guide a more informed decision.

Steel is renowned for its superior tensile strength and high load-bearing capacity, making it a viable option for applications that prioritize structural strength. However, steel is significantly denser and heavier than aluminum, rendering it less favorable for scenarios where weight is a limiting factor. Furthermore, unless treated or coated, steel is susceptible to corrosion, especially in humid or coastal settings.

Conversely, Aluminum Profiles For Air Handling Units strike a harmonious balance between strength and weight, which positions them as a versatile solution for various AHU applications. Although aluminum may not possess the absolute strength of steel, it provides ample support for most HVAC system needs while being easier to handle and install. Additionally, aluminum’s resistance to corrosion, without requiring additional coatings, surpasses that of untreated steel, ensuring long-lasting durability.

Cost considerations also play a role. While the initial investment in aluminum profiles may be higher compared to steel, the long-term benefits, including reduced maintenance and a prolonged lifespan, can offset the upfront expense. Consequently, for the majority of air handling unit installations, aluminum profiles offer an optimal blend of performance, durability, and cost-efficiency.

Primary Advantages of Using Aluminum Profiles in HVAC Applications

Aluminum profiles are extensively used across HVAC systems due to a range of inherent benefits. Let’s delve into the primary advantages that position aluminum as a preferred material in the industry.

1. Simplified Assembly and Installation

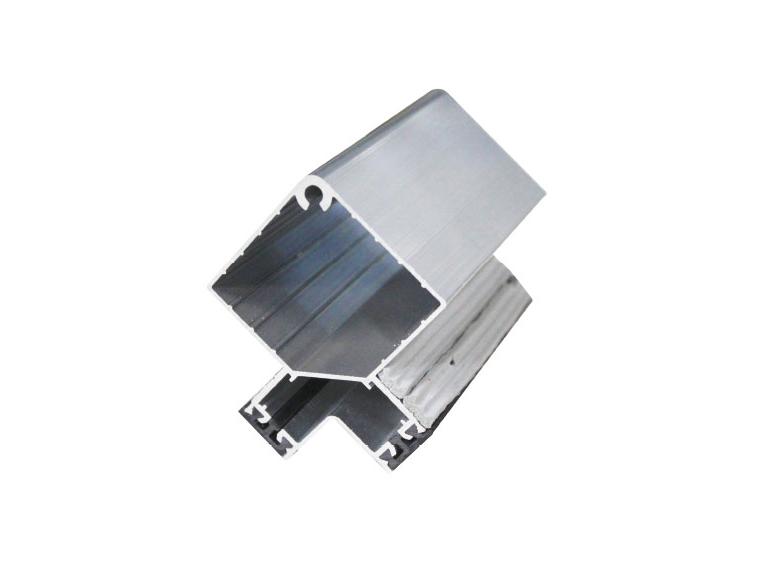

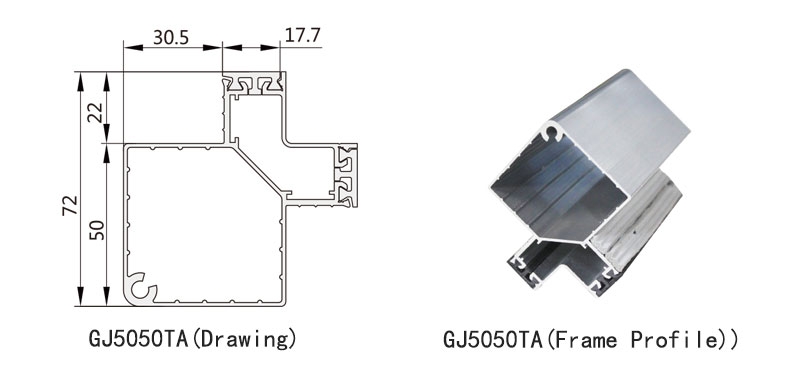

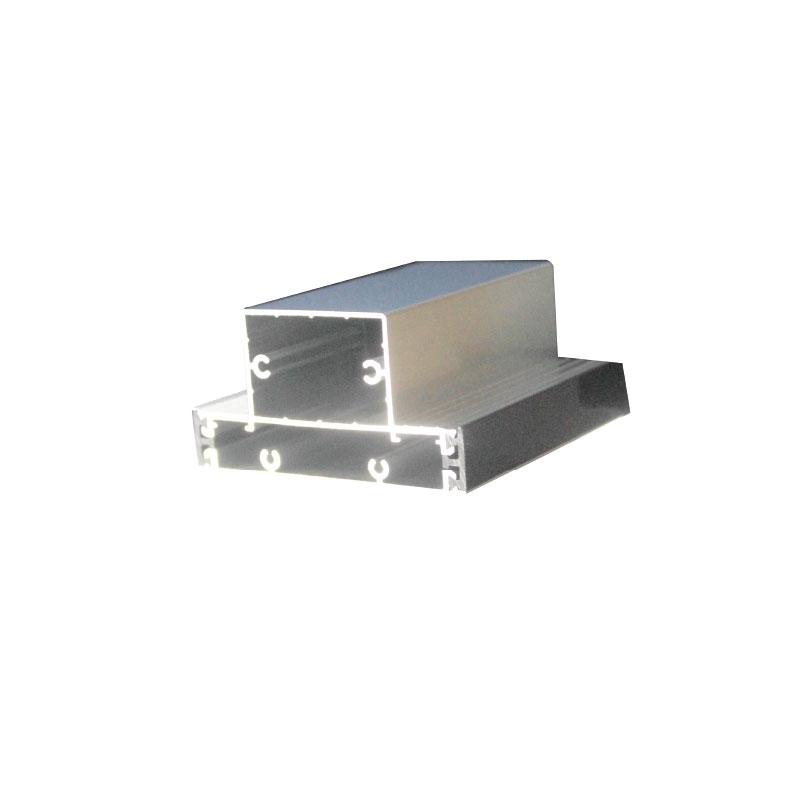

One notable advantage of aluminum profiles in AHU construction is the ease of assembly. These profiles are typically designed with built-in grooves and slots that enable quick attachment of various internal components, such as fans, filters, and coils. This reduces the time required for assembly and allows projects to be completed more swiftly.

Moreover, the lightweight nature of aluminum makes it easier to handle during the installation process. This reduces dependency on heavy lifting equipment and lessens the risk of injury or installation errors, further improving overall project efficiency.

2. Superior Corrosion Resistance and Longevity

Aluminum’s natural formation of an oxide layer upon exposure to air provides a self-sustaining barrier against corrosion. This makes it an ideal choice for AHUs, which often operate under varying conditions of humidity and temperature. Unlike steel, which requires additional protective coatings or treatments, aluminum’s resistance to rusting ensures it remains structurally intact and aesthetically appealing over a prolonged period.

This inherent corrosion resistance extends the lifespan of the AHU framework, thus reducing the frequency of costly repairs or replacements, and contributing to overall cost savings.

3. Remarkable Strength and Load-Bearing Capacity

Despite being lighter than steel, aluminum exhibits impressive strength and load-bearing capabilities. Modern Aluminum Profiles For Air Handling Units are engineered to withstand considerable stress and pressure, making them suitable for supporting the internal components of AHUs. This high strength-to-weight ratio is particularly advantageous in applications where weight minimization is crucial, such as rooftop installations or in constrained mechanical spaces.

Innovative Design Trends in Aluminum Profiles for Enhanced Air Handling Efficiency

Continuous advancements in aluminum profile design have led to the development of more efficient and adaptable air handling units. Breakthroughs in extrusion technology and materials engineering have enabled the creation of profiles that not only meet but exceed the requirements for airflow optimization, structural integrity, and insulation performance.

1. Custom Shapes and Configurations for Versatility

Aluminum Profiles For Air Handling Units can be extruded into various shapes and sizes, granting engineers the flexibility to develop custom solutions tailored to specific HVAC demands. This adaptability allows for the inclusion of features such as additional slots, grooves, or mounting points, which streamline the installation of sensors, panels, and other ancillary equipment.

2. Enhanced Thermal and Acoustic Properties for Improved Comfort

Contemporary Aluminum Profiles For Air Handling Units can be designed to incorporate thermal breaks or acoustic insulation layers, which significantly enhance the energy efficiency and noise reduction characteristics of the AHU. For installations where thermal efficiency is paramount, insulated aluminum profiles can effectively minimize heat transfer, optimizing the overall performance of the HVAC system and contributing to energy savings.

3. Aesthetic and Durability Enhancements Through Finishing Options

Aluminum profiles can undergo anodizing or powder coating processes to improve their durability and aesthetic appeal. Anodizing increases surface hardness and resistance to abrasion, while powder coating provides an additional layer of protection and expands the range of available color options. This makes aluminum profiles not only functionally superior but also visually adaptable to various architectural styles.

Aluminum Profiles: A Lightweight Solution for Heavy-Duty Air Handling Needs

The structural design of air handling units demands materials that are robust enough to support the system’s weight yet light enough to not impose excessive strain on the overall HVAC structure. Aluminum Profiles For Air Handling Units offer an ideal solution to this conundrum.

Their low weight reduces the load on building structures, particularly in high-rise buildings or in installations where space is at a premium. Simultaneously, the profiles maintain sufficient strength to support heavy components like fans, filters, and coils.

Furthermore, the thermal properties of aluminum contribute to enhanced energy efficiency. The lower thermal conductivity of aluminum compared to steel minimizes heat transfer through the AHU framework, helping to stabilize internal temperatures and reducing the risk of energy loss.

Conclusion

Aluminum Profiles For Air Handling Units have established themselves as an integral component in contemporary air handling unit design, providing an unrivaled combination of lightweight, structural strength, and versatility. Whether for standard or custom-built AHUs, aluminum profiles offer a reliable and durable solution that meets the diverse requirements of modern HVAC applications.

For industry-leading suppliers such as E-ZONG, delivering top-quality aluminum profiles for air handling units translates into empowering HVAC professionals to design and implement efficient, durable, and cost-effective systems. As innovation within the HVAC industry continues to push boundaries, aluminum profiles are poised to remain at the forefront of material solutions, shaping the future of air handling units for years to come.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution -

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow -

The Sleek and Efficient Linear Slot Diffuser for Air Vent

The Sleek and Efficient Linear Slot Diffuser for Air Vent -

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors -

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door -

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency -

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces -

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent -

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions -

Elegant & Durable: Premium Swing Door Protection for Hospitals

Elegant & Durable: Premium Swing Door Protection for Hospitals

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind