Biopharmaceutical Cleanroom Doors: Ensuring Sterility, Safety, and Compliance

- By:hqt

- 2025-02-26

- 29

Why are cleanroom environments crucial in biopharmaceutical facilities? They maintain sterility and prevent contamination, ensuring product safety and quality. Cleanroom doors play a vital role in this process by regulating the environment and blocking unwanted particles from entering.

E-ZONG has extensive experience in this field and holds several key patents, including the Appearance Design Patent, Invention Patent, and Practical Patent. The company has also achieved ISO9001 quality management system certification. Designed to meet GMP standards and safety regulations, E-ZONG's cleanroom doors help maintain cleanliness and security in controlled environments.

Importance of Cleanroom Doors in Biopharmaceutical Facilities

Cleanroom doors play a key role in biopharmaceutical facilities. They help maintain a clean and controlled environment. Without proper doors, outside contamination can enter sensitive areas. This can affect the quality of products and cause serious risks.

Sterility Control

Cleanroom doors help keep germs and unwanted particles out. Biopharmaceutical products must be made in a clean space. Even small amounts of dust or microbes can cause problems. Special doors help prevent contamination by sealing off controlled areas.

These doors are made from materials that do not collect dust or bacteria. They also have smooth surfaces that are easy to clean. Some doors have antimicrobial coatings to stop the growth of harmful microbes. This helps keep the cleanroom safe and reduces the risk of contamination.

Environmental Separation

Different areas in a cleanroom have different air pressures. This helps control airflow and prevents contamination from spreading. Cleanroom doors help maintain these pressure differences. They create a strong barrier between different zones.

When a cleanroom door closes, it forms a tight seal. This stops air from moving freely between areas. Some doors have special pressure-regulated systems. These systems help keep the right balance of air pressure inside the cleanroom.

Ease of Access & Workflow Efficiency

Workers in biopharmaceutical facilities need to move quickly and safely. Cleanroom doors make movement easy while keeping the environment protected. Some doors open automatically, so workers do not have to touch them. This reduces the risk of contamination.

Cleanroom doors are also designed for the smooth movement of materials. Large doors allow equipment and supplies to pass through easily. This improves workflow and makes operations more efficient.

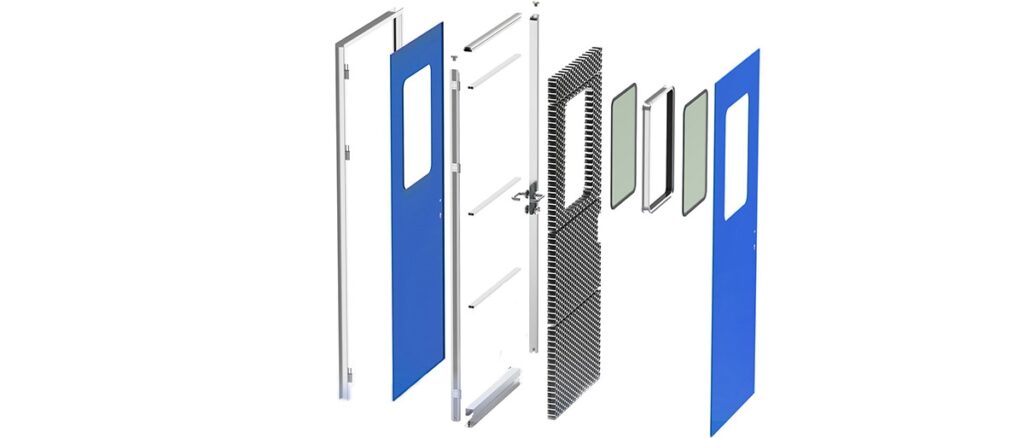

Key Features of Biopharmaceutical Cleanroom Doors

Cleanroom doors are built with special features to meet strict requirements. These features help maintain cleanliness, safety, and efficiency.

Material Composition

Cleanroom doors must be strong and resistant to damage. They are made from high-quality materials such as:

- Stainless steel - Strong, durable, and easy to clean.

- Fiberglass - Lightweight and resistant to chemicals.

- Colored GI panel - Aesthetic and rust-proof.

- SUS panel - Corrosion-resistant and long-lasting.

- HPL (High-Pressure Laminate) - Scratch-resistant and smooth.

These materials prevent rust and corrosion. They also help maintain a sterile environment by resisting chemical damage.

Automatic vs. Manual Operation

Cleanroom doors can be either manual or automatic. Automatic doors are useful in sterile environments. They open without touch, which helps prevent contamination. Manual doors are also available and are designed to be easy to operate.

Sealing Mechanisms

A proper seal is important in cleanroom doors. These doors have features that prevent dust and air from leaking through. The sealing mechanisms include:

- Air-tight systems - Prevent outside air from entering.

- Pressure-regulated seals - Maintain cleanroom pressure balance.

- Dust-proof barriers - Stop small particles from passing through.

Customization

Different cleanrooms have different needs. Cleanroom doors can be customized for:

- Various cleanroom classifications - Different levels of cleanliness require different door designs.

- Process needs - Some doors are made for high-security areas, while others allow fast access for workers.

Innovations in Cleanroom Door Technology

Technology is making cleanroom doors smarter and more effective. New designs help improve safety, efficiency, and hygiene.

Smart Doors with Sensor Technology

Smart doors use advanced sensors to improve convenience and security. Some of the latest technologies include:

- Swing automatic door motor - Detects movement and opens without touch. This reduces contamination risks.

- Foot reaction switch - Allows users to open doors by pressing a switch with their foot. This helps when hands are busy or contaminated.

- Face recognition switch - Uses face recognition technology to identify authorized personnel. This improves security and efficiency.

These smart features help control access and reduce the spread of contamination.

Self-Decontaminating Surfaces

Some cleanroom doors now have antimicrobial coatings. These coatings kill germs on contact. They help reduce the risk of contamination and keep the cleanroom safer.

Energy-Efficient and Sustainable Materials

Modern cleanroom doors are also designed to be eco-friendly. They use materials that meet environmental standards while maintaining durability and cleanliness. These doors help reduce energy waste and comply with sustainability regulations.

Why Choose E-ZONG for Biopharmaceutical Cleanroom Doors

E-ZONG (Yizhong) is a trusted company in the cleanroom industry. It has years of experience in making high-quality cleanroom doors. Many businesses around the world choose E-ZONG for their cleanroom solutions.

Extensive Experience

E-ZONG has been in the industry for over 26 years. The company has worked on large-scale projects and has strong expertise in quality control. Every order is carefully handled to meet customer needs.

Global Reach

E-ZONG exports its products to many countries around the world. Its market includes North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, the Middle East, and East Asia. This broad presence demonstrates that E-ZONG's products meet international standards and are trusted by businesses in different regions.

Advanced Technology and High Standards

E-ZONG uses the latest manufacturing techniques and high-quality materials. The company focuses on environmental aluminum products and aims to create top-standard cleanroom doors.

The company also follows strict quality testing processes. This ensures that every door meets the highest standards for safety and performance.

Get E-ZONG Cleanroom Doors Today!

E-ZONG makes high-quality cleanroom doors. Many businesses use them worldwide. They are strong, safe, and easy to clean. They help keep cleanrooms free from contamination.

E-ZONG has over 26 years of experience. It provides doors that meet strict industry standards. Companies in North America, South America, Europe, Asia, and more trust E-ZONG.

Need cleanroom doors? Choose E-ZONG for reliable and durable solutions. Contact us now!

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution -

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow -

The Sleek and Efficient Linear Slot Diffuser for Air Vent

The Sleek and Efficient Linear Slot Diffuser for Air Vent -

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors -

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door -

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency -

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces -

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent -

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions -

Elegant & Durable: Premium Swing Door Protection for Hospitals

Elegant & Durable: Premium Swing Door Protection for Hospitals

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind