Designing a Flexible Clean Room Aluminum Profile System

- By:hqt

- 2024-10-22

- 29

Contemplating Industry Challenges

Have you ever pondered the significant hurdles that various industries encounter while striving to maintain environments devoid of contamination? Clean rooms are indispensable in fields such as pharmaceuticals, semiconductors, and biotechnology, where even the tiniest particle can threaten product integrity. These specialized settings are meticulously designed to uphold rigorous cleanliness standards, thereby safeguarding the delicate nature of sensitive processes and products.

Clean rooms are required to comply with stringent regulations, including those set forth by the International Organization for Standardization (ISO). These guidelines specify the permissible levels of contaminants and dictate the materials and construction methodologies necessary for adherence. As industries continue to progress, the need for versatile and efficient clean room solutions escalates, underscoring the pivotal role that clean room aluminum profile system plays in contemporary construction.

Comprehending Clean Room Aluminum Profiles

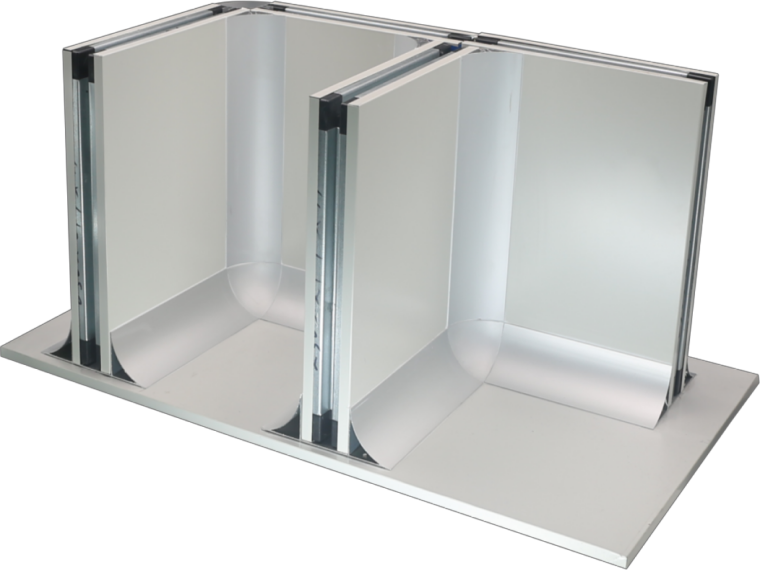

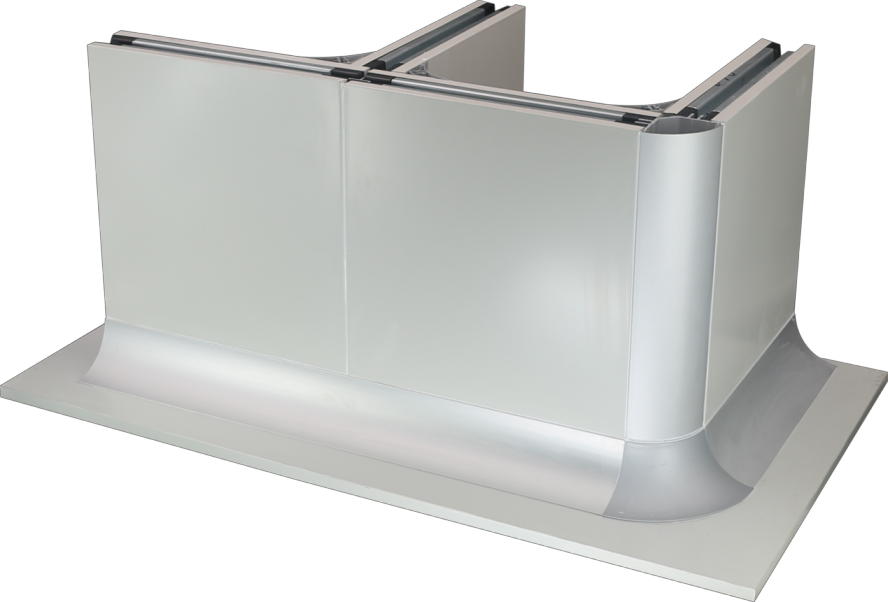

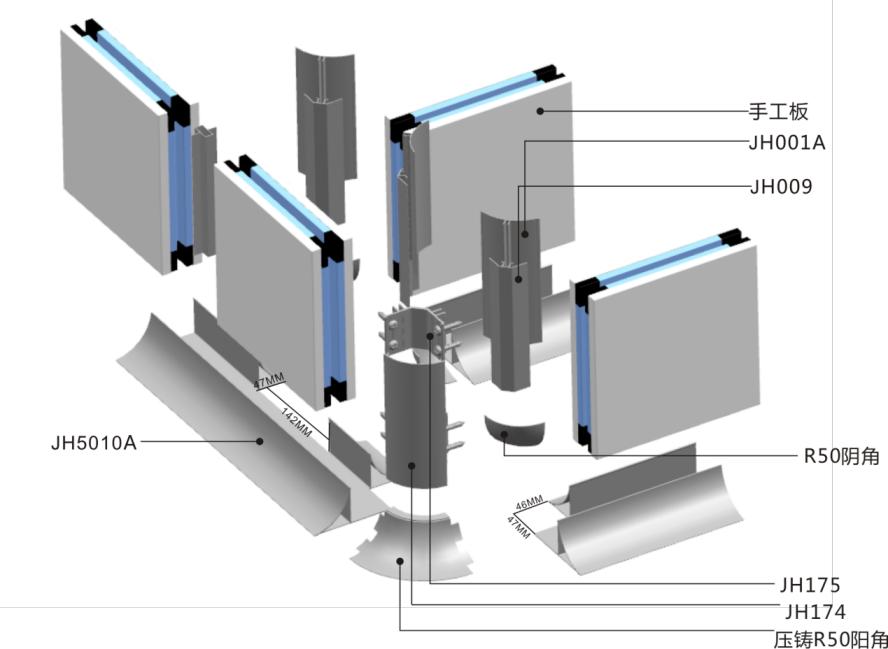

Foundation of Modular Designs

Clean room aluminum profiles serve as the fundamental building blocks for creating the frameworks and structures essential for modular clean room configurations. Crafted specifically to enhance clean room sandwich panels, doors, and windows, these profiles deliver a cohesive and efficient system. The superior quality of the materials ensures that these profiles satisfy the exacting standards required for clean room applications, making them a fundamental element of clean room construction.

Manufactured via a specialized extrusion process, these profiles can be customized to meet various specifications, accommodating a range of shapes and sizes. This level of customization is crucial for achieving the intended design and functionality in clean room settings, thereby enabling smooth integration with existing systems and equipment.

Advantages of Aluminum Profiles in Clean Rooms

Enhancing Suitability for Controlled Environments

Clean room aluminum profiles present a myriad of benefits that bolster their appropriateness for controlled environments. Among the most significant advantages is their lightweight yet robust construction. This characteristic allows for straightforward handling and installation while ensuring they can endure the demanding conditions inherent in clean room operations.

Moreover, aluminum profiles exhibit remarkable resistance to corrosion, which is vital for preserving their integrity over extended periods. Their ease of cleaning further supports longevity and performance, guaranteeing that they remain sterile and functional throughout their operational lifespan in clean room contexts.

Improving Clean Room Airflow and Efficiency

Airflow Optimization Strategies

Airflow management is a crucial element of clean room design, significantly impacting contamination control and energy efficiency. Clean Room Aluminum Profile System can be designed to optimize airflow patterns, effectively reducing dead zones where particles are likely to accumulate. By strategically incorporating these profiles, facility managers can significantly enhance ventilation efficiency and improve the overall quality of the air.

Effective management of airflow not only mitigates contamination risks but also contributes to energy conservation. By maximizing the efficiency of heating, ventilation, and air conditioning (HVAC) systems, aluminum profiles facilitate the creation of a more sustainable clean room environment, aligning with the industry's increasing focus on eco-friendliness.

Operational Streamlining

The modular nature of clean room aluminum profiles enables adaptable configurations that can swiftly respond to evolving operational needs. This flexibility ensures that clean rooms can evolve in tandem with technological advancements and shifting industry demands. As processes become more intricate, the capability to reconfigure layouts without extensive renovations proves invaluable.

In addition, the straightforward integration of supplementary equipment and systems into these profiles enhances operational efficiency. This adaptability allows facilities to promptly address new challenges while upholding compliance with cleanliness standards.

The Significance of Aluminum Profiles in Clean Room Compliance

Adhering to Stringent Standards

Designed with specific cleanliness criteria in mind, clean room aluminum profiles play a crucial role in ensuring compliance. By utilizing materials and construction methods that align with ISO regulations, these profiles help guarantee that clean rooms meet the highest standards for air purity and particle control.

Furthermore, these profiles facilitate the installation of essential equipment, such as HEPA filters and airlocks, which are vital for maintaining controlled environments. This compliance is especially critical for industries subjected to rigorous regulatory oversight, where non-compliance can result in severe repercussions.

Addressing Industry Demands

In sectors such as pharmaceuticals, the stakes are alarmingly high. Clean room aluminum profiles are fundamental in ensuring that manufacturing processes are conducted within sterile environments. By providing structural integrity and bolstering compliance with Good Manufacturing Practices (GMP), these profiles are essential in safeguarding public health.

Additionally, clean room profiles are crucial in research and development contexts, where innovation is predicated on the maintenance of uncontaminated environments. The importance of these profiles in supporting product quality and scientific integrity cannot be overstated.

Selecting the Appropriate Clean Room Aluminum Profile System

Evaluating Specific Requirements

When determining the most suitable Clean Room Aluminum Profile System, it is imperative to assess specific needs thoroughly. Factors such as the intended function of the clean room, the requisite level of cleanliness, and the available space all influence the selection of profiles.

A comprehensive evaluation of operational requirements will inform decisions regarding profile configurations, ensuring that the ultimate design aligns with the facility's objectives. Collaborating with suppliers like E-ZONG can yield valuable insights and options tailored to unique applications.

Customization and Adaptability

Clean room aluminum profiles come in various forms and dimensions, allowing for bespoke solutions that cater to specific projects. The modular design features inherent in these profiles enable facilities to create distinctive configurations that accommodate different workflows and equipment.

With functionalities like T-slots for effortless attachment and customization, these profiles significantly enhance the versatility of clean room designs. This adaptability is vital in environments that may necessitate frequent updates or modifications to layouts.

Future Developments in Clean Room Construction

Advancements in Profile Design

As the demand for sophisticated clean room solutions continues to surge, innovations in aluminum profile design are emerging. Manufacturers are increasingly investing in research and development to create profiles that enhance efficiency, cleanliness, and sustainability.

One anticipated trend involves the integration of smart technologies into aluminum profiles, enabling real-time monitoring of environmental conditions. This evolution will empower facility managers to proactively address potential contamination risks and improve overall operational oversight.

Emphasis on Sustainability

The rising focus on sustainability is reshaping the landscape of clean room construction. Given that aluminum profiles are inherently recyclable, they represent an environmentally conscious option for clean room projects. As industries endeavor to minimize their ecological footprint, the incorporation of sustainable materials will become ever more significant.

Moreover, innovations aimed at decreasing energy consumption during clean room operations will propel trends in profile development. By concentrating on designs that bolster energy efficiency, manufacturers can foster more sustainable practices within the clean room sector.

Conclusion

Clean room aluminum profile systems are indispensable for establishing effective, compliant, and flexible clean room environments. Their lightweight yet durable construction, combined with customization capabilities, positions them as the premier choice across various industries.

As clean room standards continue to evolve, the significance of these profiles in maintaining contamination-free environments will only amplify. Partnering with reputable suppliers such as E-ZONG ensures that facilities receive top-tier solutions tailored to their specific requirements. Embracing innovation and sustainability will pave the way for the future of clean room design, reinforcing the vital role of aluminum profiles in safeguarding both products and public health.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution -

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow -

The Sleek and Efficient Linear Slot Diffuser for Air Vent

The Sleek and Efficient Linear Slot Diffuser for Air Vent -

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors -

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door -

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency -

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces -

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent -

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions -

Elegant & Durable: Premium Swing Door Protection for Hospitals

Elegant & Durable: Premium Swing Door Protection for Hospitals

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind