Best Cleanroom Aluminum Profiles & Parts for Contamination-Controlled Environments

- By:hqt

- 2024-12-16

- 29

In today’s world, the cleanliness of production environments is more critical than ever. But have you ever wondered how high-tech industries maintain their super-clean environments, such as semiconductor manufacturing, pharmaceutical labs? The answer lies in specialized cleanroom equipment and materials, with one key component being Cleanroom Aluminum Profiles & Parts. These materials are essential for building the infrastructure that helps preserve the purity of controlled spaces, ensuring that contamination is minimized, and operations run smoothly.

What is Cleanroom Equipment?

Cleanroom equipment refers to a variety of tools and devices designed to create and maintain highly controlled, sterile environments. These environments are used in industries where even the smallest contamination can lead to product failure or compromised research, such as in pharmaceutical production, microelectronics manufacturing, and biotechnology research. Cleanrooms are environments where air quality, temperature, humidity, and particulate levels are strictly controlled to ensure that operations are conducted without contamination risks.

Key Cleanroom Equipment

The main types of cleanroom equipment include HVAC systems, air filters, diffusers, laminar air flow units, and more. The HVAC (Heating, Ventilation, and Air Conditioning) system is crucial in regulating the airflow and temperature in a cleanroom. These systems are designed to remove excess moisture, pollutants, and heat from the air, while maintaining an optimal environment for both humans and machinery.

In addition to HVAC, cleanroom air filters and laminar air flow units are essential for controlling the concentration of airborne particles. These devices ensure that cleanroom air is free from dust, bacteria, and other contaminants that could disrupt sensitive processes. Cleanrooms are often equipped with specific types of walls—hard walls or soft walls—depending on their intended use and the level of contamination control required.

Cleanroom Equipment Market Growth

The cleanroom equipment market has experienced significant growth in recent years, reflecting the increasing demand for cleanroom solutions across various industries. From $2.84 billion in 2023, the market is expected to grow to $3.05 billion in 2024, at a compound annual growth rate (CAGR) of 7.1%. This growth is largely driven by sectors like semiconductor manufacturing, healthcare, electronics production. In fact, the demand for cleanrooms is expected to surge even further, with projections indicating the market will reach $4.04 billion by 2028, growing at a CAGR of 7.3%.

Factors Driving Market Growth

Several factors are driving the growth of the cleanroom equipment market, including the expansion of the biopharmaceutical industry, advances in biotechnology research, and the ever-increasing need for contamination control in manufacturing processes. The demand for flexible cleanroom solutions—cleanrooms that can be easily customized or relocated—is also on the rise. As the industry evolves, the cleanroom environment must adapt, incorporating smart technology and more modular designs to meet diverse operational needs.

Additionally, recent global events such as the COVID-19 pandemic have emphasized the importance of cleanroom technology in industries such as healthcare and research. As a result, the adoption of new, innovative solutions in cleanroom design and equipment has gained momentum.

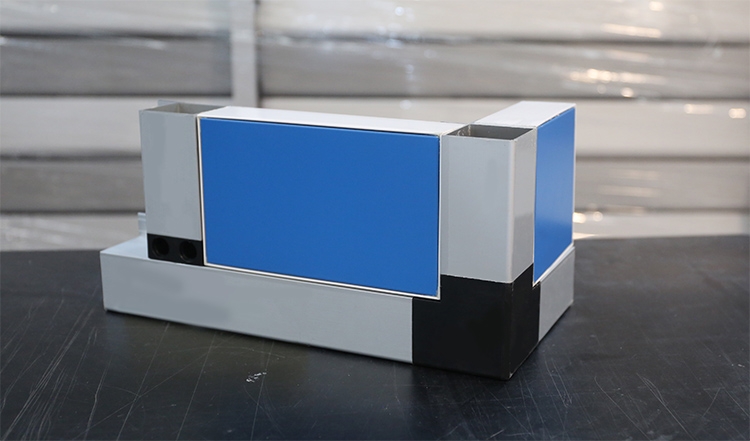

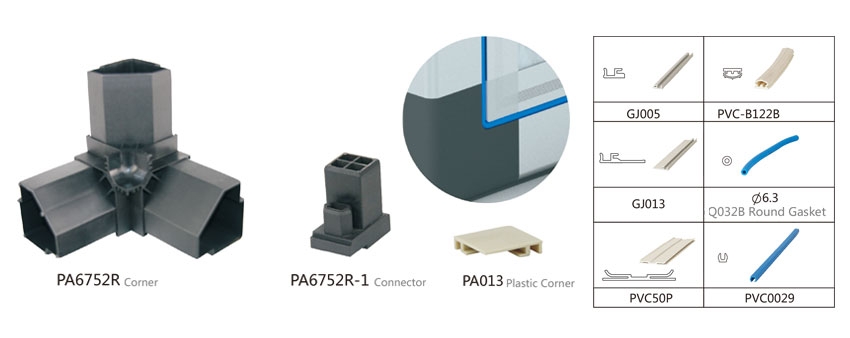

Cleanroom Aluminum Profiles & Parts: Essential for Structural Integrity

One critical component of cleanroom infrastructure is the aluminum profile. Cleanroom Aluminum Profiles & Parts are used to construct the framework and support structures for various cleanroom equipment and systems. They are versatile, durable, and customizable, making them an ideal choice for building cleanroom environments that require high levels of contamination control.

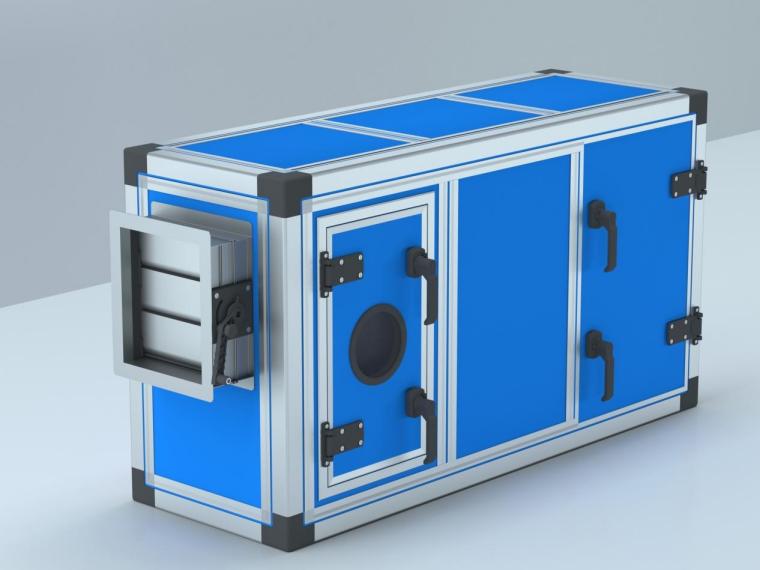

AHU Aluminum Profiles: Building Air Handling Units

One of the most important applications for aluminum profiles in cleanroom environments is in the construction of Air Handling Units (AHUs). AHUs are used in cleanrooms to manage the airflow, regulate air quality, and maintain the sterile conditions necessary for sensitive processes. The use of AHU aluminum profiles ensures that these units are not only strong and durable but also lightweight and easy to assemble.

AHU aluminum profiles are typically made from high-quality aluminum alloys that are resistant to corrosion, ensuring long-term reliability in demanding environments. These profiles are designed with specific grooves and slots to make it easy to attach internal components such as filters, fans, and coils, all of which are critical for proper air management.

Benefits of AHU Aluminum Profiles

The advantages of using aluminum profiles in AHU construction are numerous. First and foremost, aluminum is lightweight yet strong, offering high load-bearing capacity without compromising the structural integrity of the unit. Additionally, aluminum profiles are corrosion-resistant, which is crucial in maintaining the longevity and efficiency of AHUs in the high-humidity environments often found in cleanrooms.

Another significant advantage is customizability. Aluminum profiles can be easily machined to meet specific design requirements, allowing manufacturers to create AHUs that are perfectly suited for their applications. Whether the unit needs to be adjusted for size, airflow requirements, or specific mounting configurations, aluminum profiles can be adapted accordingly.

Furthermore, ease of assembly is a key benefit. The modular design of aluminum profiles simplifies the process of assembling AHUs, reducing installation time and labor costs. This flexibility is essential for industries that require quick deployment or adjustments in their cleanroom systems.

Why Choose E-ZONG for Cleanroom Aluminum Profiles & Parts?

When it comes to cleanroom infrastructure, the quality of materials is critical. This is where E-ZONG shines as a supplier of top-quality Cleanroom Aluminum Profiles & Parts. E-ZONG specializes in providing a wide range of aluminum profiles for cleanroom applications, including AHU frames, cleanroom walls, and other structural components.

E-ZONG's Quality and Expertise

E-ZONG stands out in the market for its commitment to high-quality aluminum and precision manufacturing. The company offers a range of standard and custom-designed profiles, ensuring that clients receive products that meet their exact specifications. Whether you're looking for a standard solution or a highly customized cleanroom design, E-ZONG has the expertise to provide durable and efficient aluminum profiles that help create the perfect cleanroom environment.

Sustainability and Innovation

As cleanroom technology continues to evolve, E-ZONG is at the forefront of innovation. The company not only focuses on providing high-quality aluminum products but also emphasizes sustainability in manufacturing. E-ZONG’s aluminum profiles are designed to be recyclable, reducing the environmental footprint of cleanroom construction. Additionally, the company’s continuous research and development efforts ensure that it remains aligned with industry trends, providing cutting-edge solutions that address the changing needs of the cleanroom industry.

Conclusion

In the fast-evolving world of cleanroom environments, where even the smallest speck of dust can have significant consequences, aluminum profiles, and parts play a crucial role. From building sturdy frameworks for air handling units to constructing custom cleanroom walls and support systems, these components provide the strength, flexibility, and corrosion resistance needed to maintain a sterile, contamination-free environment.

As the cleanroom equipment market continues to expand, driven by innovations in biotechnology, healthcare, and other high-tech industries, the demand for reliable and high-quality Cleanroom Aluminum Profiles & Parts will only increase. E-ZONG, with its advanced solutions and commitment to quality, is perfectly positioned to meet this growing demand and provide industries with the tools they need to maintain the highest standards of cleanliness and safety.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution -

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow -

The Sleek and Efficient Linear Slot Diffuser for Air Vent

The Sleek and Efficient Linear Slot Diffuser for Air Vent -

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors -

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door -

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency -

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces -

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent -

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions -

Elegant & Durable: Premium Swing Door Protection for Hospitals

Elegant & Durable: Premium Swing Door Protection for Hospitals

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind