Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know

- By:hqt

- 2024-10-22

- 29

Key Characteristics to Consider in Cleanroom Aluminum Profiles

The Significance of Quality in Cleanroom Aluminum Profiles

In the realm of cleanroom construction, the selection of materials plays an indispensable role. Cleanroom aluminum profiles act as vital components that underpin modular sandwich wall panels, thereby safeguarding the integrity of the cleanroom atmosphere. The significance of quality cannot be overstated; even the most minor contamination can jeopardize rigorous cleanliness standards. Consequently, it is imperative that a trusted wholesaler of cleanroom aluminum profiles, such as E-ZONG, supplies profiles that conform to global cleanliness benchmarks, particularly those set forth by the International Organization for Standardization (ISO).

These profiles must be engineered specifically for cleanroom applications, necessitating their ability to endure stringent cleaning protocols without compromising structural integrity. By opting for profiles that combine lightweight characteristics with durability, businesses can ensure that their cleanroom structures maintain safety and efficacy over extended durations.

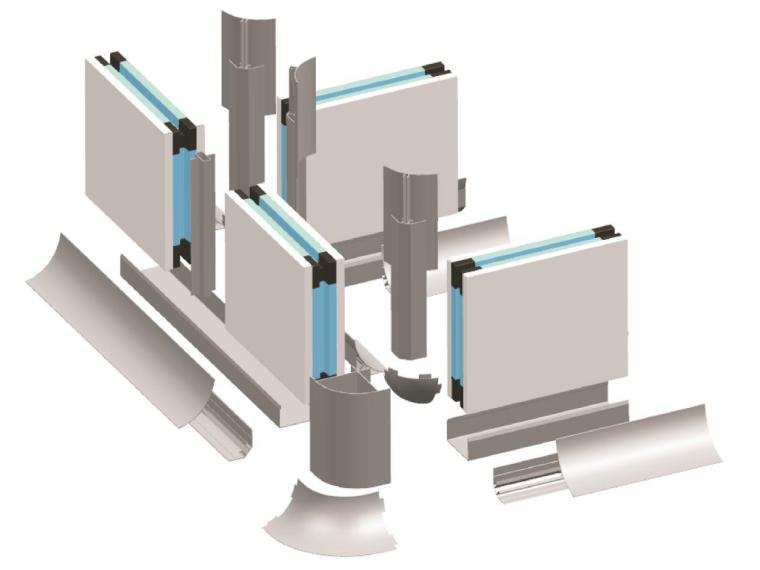

Furthermore, a wholesaler should offer an array of products tailored to meet diverse cleanroom specifications. Whether the need arises for profiles suited for pharmaceutical manufacturing or semiconductor production, versatility emerges as a pivotal feature. Cleanroom Aluminum Profile Wholesaler like E-ZONG, for instance, provides an extensive selection of shapes and sizes, enabling clients to tailor their cleanroom designs to align with specific operational requirements.

Durability and Resistance to Contaminants

Among the prominent features of cleanroom aluminum profiles is their remarkable resistance to both corrosion and contaminants. Cleanrooms frequently employ harsh cleaning agents to uphold sterility, necessitating that materials withstand such substances without succumbing to degradation. The profiles offered by E-ZONG are meticulously designed to resist corrosion, rendering them ideal for environments where cleanliness is of utmost importance.

Additionally, the lightweight properties of aluminum enhance its durability. Cleanroom operations demand that equipment and structures be both resilient and easily manipulable. The profiles available from reputable wholesalers facilitate straightforward assembly and disassembly, which is crucial for ongoing maintenance and modifications within cleanroom environments.

In addition to these pragmatic advantages, the aluminum profiles can be enhanced through powder coating or anodizing, thereby increasing their resistance to wear and tear. This supplementary layer of protection not only prolongs the lifespan of the profiles but also elevates their aesthetic appeal, ensuring that cleanrooms exude a professional appearance while functioning effectively.

Evaluating Cleanroom Aluminum Profiles Against Alternative Materials: Which Reigns Supreme?

The Advantages of Utilizing Aluminum Profiles

When conducting a comparative analysis of cleanroom aluminum profiles versus alternative materials such as stainless steel or plastic, aluminum distinctly stands out for several compelling reasons. Primarily, the lightweight nature of aluminum simplifies installation and modifications, a critical factor in cleanroom environments where flexibility and adaptability are essential for maintaining operational efficiency.

Aluminum is also known for its superior strength-to-weight ratio, allowing even thinner profiles to bear substantial loads without compromising structural integrity. In settings where stringent cleanliness is required, the capacity to utilize lightweight yet robust materials alleviates stress on the overall cleanroom structure.

Moreover, aluminum boasts inherent resistance to rust and corrosion, establishing it as a more sustainable choice in environments that necessitate frequent cleaning. In contrast, materials like steel may deteriorate due to rust, posing a contamination risk. Therefore, for cleanroom applications, aluminum profiles represent a safer and more efficient alternative.

The Cost-Effectiveness of Aluminum

Another crucial aspect to consider is the cost-effectiveness associated with cleanroom aluminum profiles. Although the initial investment may be a factor, the potential long-term savings related to maintenance and replacements render aluminum profiles economically advantageous. Their durability and corrosion resistance allow businesses to benefit from lower lifecycle costs in comparison to other materials that may necessitate more frequent replacements or repairs.

Furthermore, the versatility inherent in aluminum profiles supports innovative designs capable of adapting to a wide range of requirements. This adaptability can yield time savings during both the construction phase and the ongoing operations of a cleanroom, further enhancing overall cost efficiency.

In summary, while alternative materials may possess their own strengths, the distinctive attributes of aluminum profiles position them as the superior choice for cleanroom applications.

Enhancing Workplace Safety and Efficiency with Cleanroom Aluminum Profiles

Promoting Workplace Safety

Safety remains a paramount concern within cleanroom environments, particularly in industries such as pharmaceuticals and semiconductors, where even slight contamination can have grave consequences. Cleanroom aluminum profiles bolster workplace safety by offering robust and reliable structures that underpin cleanroom operations.

These profiles are meticulously crafted to meet stringent safety regulations, thereby reducing the likelihood of structural failures. Their corrosion-resistant characteristics further support the maintenance of a contamination-free environment, thereby minimizing risks linked to degrading materials.

Moreover, the lightweight nature of aluminum enhances safety during installation and maintenance tasks. Employees can manage the profiles with ease, minimizing the risk of injury associated with heavier materials and contributing to a safer working environment.

Enhancing Operational Efficiency

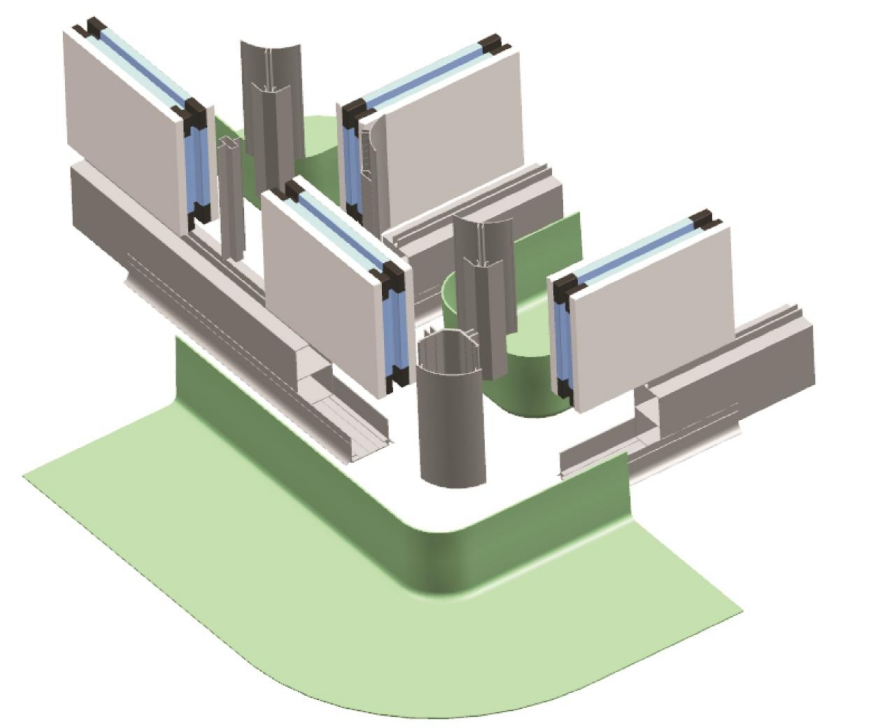

In addition to safety, cleanroom aluminum profiles can dramatically enhance operational efficiency. Their modular design facilitates rapid assembly and reconfiguration, empowering businesses to adapt their cleanroom layouts in response to evolving operational demands.

Furthermore, the ease with which aluminum profiles can be cleaned allows for swift maintenance, thereby minimizing downtime. Regular cleaning is vital for preserving the integrity of cleanroom environments, and aluminum’s resistance to aggressive cleaning agents renders it an ideal material for such purposes.

The versatility of these profiles also enables effective integration with various cleanroom systems and equipment. Features like T-slots allow for modular configurations that streamline operations and improve workflow efficiency.

The Process of Sourcing Cleanroom Aluminum Profiles: From Concept to Completion

The Initial Consultation Phase

The journey of sourcing cleanroom aluminum profiles commences with an initial consultation between the wholesaler and the client. This foundational step is crucial, as it enables the wholesaler to gain a thorough understanding of the specific requirements pertaining to the cleanroom project. Critical factors such as dimensions, shapes, and cleanliness standards must be examined to ensure the selection of appropriate profiles.

During this consultative process, Cleanroom Aluminum Profile Wholesaler like E-ZONG can provide valuable insights regarding the optimal materials and designs to fulfill the client’s operational needs. Their expertise serves as an essential resource for clients navigating the complexities of cleanroom design and construction.

Customization and Manufacturing Process

Upon establishing the requirements, the subsequent step entails customizing the profiles. Cleanroom Aluminum Profile Wholesaler like E-ZONG, for instance, offers a plethora of customization options, enabling clients to define features such as color, finish, and dimensions. This level of personalization guarantees seamless integration of aluminum profiles with existing cleanroom frameworks.

Following the customization phase, the profiles progress to production. The manufacturing process incorporates advanced extrusion techniques specifically designed for cleanroom applications. Rigorous quality control measures are instituted throughout production to ensure that the profiles adhere to the highest standards of cleanliness and durability.

Delivery and Installation Logistics

Once production is complete, the profiles are meticulously packaged and dispatched to the client. Timely delivery is vital to maintain the momentum of cleanroom projects. Cleanroom Aluminum Profile Wholesaler like E-ZONG prides itself on efficient logistics, ensuring clients receive their materials without delay.

Upon receipt of the materials, installation can begin. The modular design of aluminum profiles allows for uncomplicated assembly, thereby reducing both installation time and labor costs. Once installed, these profiles contribute to a clean and sterile operational environment, primed for use in critical applications.

Understanding Sustainability in Cleanroom Aluminum Profile Manufacturing

The Environmental Advantages of Aluminum

As sustainability becomes increasingly vital in manufacturing sectors, cleanroom aluminum profiles are no exception to this trend. Aluminum is a recyclable material, which implies it can be repurposed multiple times without losing its inherent properties. This characteristic substantially mitigates the environmental footprint of cleanroom construction.

Moreover, the production of aluminum profiles frequently incorporates eco-friendly methodologies, such as waste reduction during the extrusion process. By selecting a Cleanroom Aluminum Profile Wholesaler like E-ZONG, which emphasizes sustainable manufacturing practices, businesses can contribute to a more environmentally friendly supply chain.

Longevity and Waste Reduction

The durability of cleanroom aluminum profiles significantly influences their sustainability credentials. With their inherent resistance to corrosion and wear, these profiles typically outlast many alternatives, resulting in a longer lifespan. This longevity translates to fewer replacements, thereby reducing waste over time.

By investing in high-quality aluminum profiles, companies can ensure the longevity of their cleanroom structures. This strategic approach aligns with the growing focus on sustainability within industrial operations, enabling businesses to meet their environmental responsibilities while optimizing operational efficiency.

A Commitment to Sustainable Practices

Opting for a reputable Cleanroom Aluminum Profile Wholesaler like E-ZONG signifies a partnership with a company that prioritizes sustainability. From the responsible sourcing of materials to environmentally considerate manufacturing processes, E-ZONG integrates sustainability at every stage of production.

Incorporating sustainability into cleanroom projects not only benefits the environment but also enhances the organization’s reputation. As consumers increasingly favor eco-conscious practices, businesses demonstrating a commitment to sustainability can secure a competitive advantage within their industries.

Conclusion

In conclusion, cleanroom aluminum profiles are not merely essential components in cleanroom construction; they embody principles of quality, efficiency, and sustainability. By collaborating with a knowledgeable wholesaler, organizations can ensure compliance with the highest standards while bolstering their operational capabilities.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution -

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow -

The Sleek and Efficient Linear Slot Diffuser for Air Vent

The Sleek and Efficient Linear Slot Diffuser for Air Vent -

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors -

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door -

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency -

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces -

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent -

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions -

Elegant & Durable: Premium Swing Door Protection for Hospitals

Elegant & Durable: Premium Swing Door Protection for Hospitals

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind