About Cleanroom Door Manufacturing

Swing Doors: These are standard hinged doors that swing open and closed like traditional doors. They are commonly used in clean rooms and are available in various materials and sealing options.

Sliding Doors: Sliding doors are designed to slide horizontally along a track, saving space compared to swing doors. They can be manual or automatic and are often used in areas with limited space.

Roller shutter door : These doors roll up vertically, similar to a garage door. They are used in areas where rapid opening and closing is required and for example logistics, warehousing and other places.

High-Speed Doors: High-speed doors are designed to open and close quickly, minimizing the time that the clean room is exposed to external contaminants. They are suitable for environments where maintaining a controlled atmosphere is crucial.

Pass-Through Doors: Pass-through doors, also known as air showers or material transfer chambers, allow the controlled transfer of materials into and out of clean rooms without direct personnel entry, reducing contamination risks.

Automatic sliding doors: Equipped with sensors, it can automatically sense the approach of people and open automatically, reducing air exchange, suitable for areas that require easy access.

Airtight Doors: Hermetic doors are designed to create an airtight seal when closed, minimizing air exchange between clean room and non-clean room areas. They are used in high-level clean rooms where strict environmental control is essential.

Fire-Rated Doors: Fire-rated doors provide both clean room separation and fire protection. They are designed to withstand fire for a specified period, ensuring safety while maintaining the clean room's integrity.

Radiation Shielding Doors: Used in facilities dealing with radioactive materials, these doors are designed to block radiation leakage and ensure the safety of personnel and the clean room environment.

Interlock Doors: Interlock doors require one door to be closed before another can be opened. They help maintain pressure differentials and prevent contaminants from entering different areas.

Cleanroom Door Certification

Cleanroom Door Certification: ISO 14644-1 Cleanroom Standards, Fire Rating Certification, Air Leakage Certification, ASTM E90 Sound Transmission Certification, Materials and Finish Compliance, Industry-Specific Regulations, Electrostatic Discharge (ESD) Compliance, Food Safety and FDA Compliance, CE Marking (European Conformity)

Cleanroom Door Is Important

Cleanroom Door Manufacturing Advantage

The advantage of cleanroom door manufacturing lies in its ability to create precisely engineered doors that ensure contamination control, adhere to regulatory standards, and optimize operational efficiency in controlled environments.

Cleanroom Door Manufacturing for Hospital

What is a cleanroom door?

What materials are cleanroom doors made from?

What are the types of cleanroom doors available?

A cleanroom door is a specially designed door used in controlled environments to maintain cleanliness, control air pressure, and prevent contamination. It's crucial for industries like pharmaceuticals, electronics, and biotechnology.

Cleanroom doors are often constructed from materials like stainless steel, aluminum, and fiberglass-reinforced plastic (FRP) due to their durability, ease of cleaning, and resistance to contamination.

Cleanroom doors come in various types, including swing doors, sliding doors, roll-up doors, and more. The choice depends on the specific requirements of the cleanroom and the access frequency.

Best Cleanroom Door Product Center

Cleanroom Door manufacturing process

The cleanroom door manufacturing process begins with design and material selection, favoring materials like stainless steel for durability and cleanliness. Components are precisely fabricated and assembled, ensuring airtight seals. Stringent quality control tests verify compliance with standards, and necessary certifications are obtained. Proper packaging is crucial for transit, followed by skilled installation and user training. The process emphasizes regulatory compliance, customization, and adherence to strict cleanliness standards for doors that maintain controlled environments.

Cleanroom Door general category

Cleanroom doors are classified into several general categories based on their design, functionality, and specific applications within controlled environments. Here are some common categories of cleanroom doors:

- Swing Doors: These are hinged doors that swing open and closed. They are suitable for areas with lower traffic and are available in single or double-door configurations.

- Sliding Doors: Sliding doors operate horizontally along tracks and are ideal for areas with limited space. They can provide a smooth, space-saving entry and exit point.

- Roll-Up Doors: Roll-up doors consist of horizontal slats that roll up into a compact housing. They are commonly used in cleanrooms where space efficiency is crucial.

- Hermetic Doors: Hermetic doors are designed to create an airtight seal when closed, preventing air leakage and minimizing contamination transfer between cleanroom zones.

- Fire-Rated Doors: These doors are designed to resist fire and are equipped with fire-resistant materials and mechanisms. They maintain the fire integrity of cleanroom compartments while allowing controlled access.

- Pass-Through Doors/Windows: Pass-through doors or windows facilitate the transfer of materials between cleanrooms and adjoining areas without compromising cleanliness. They often include interlocking mechanisms.

- Access Control Doors: These doors incorporate access control systems such as keycards, biometric readers, or keypad entry to enhance security and limit unauthorized entry.

- Airlock Doors: Airlock doors are used in airlock chambers that act as buffer zones between different cleanroom areas. They prevent cross-contamination by ensuring only one door is open at a time.

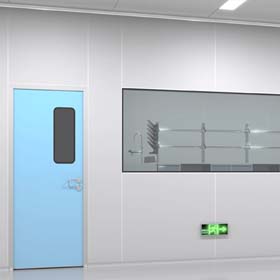

- Cleanroom View Panels: These doors or windows feature transparent panels, often made of tempered glass, that allow visibility into the cleanroom while maintaining the required cleanliness levels.

- Chemical Resistant Doors: Designed for cleanrooms handling hazardous chemicals, these doors are constructed from materials that resist chemical corrosion and contamination.

- Electrostatic Discharge (ESD) Safe Doors: These doors are designed to prevent electrostatic discharge, which can be damaging to sensitive electronic components in electronics manufacturing cleanrooms.

- Soundproof Doors: In cases where noise control is important, soundproof doors can be used to maintain quiet environments while still adhering to cleanroom standards.

- Cold Storage Doors: Cleanrooms used for cold storage applications may require doors with insulation to maintain controlled temperatures while preventing contamination.

Cleanroom Door Application Scenarios

Frequently Asked Questions

How are cleanroom doors manufactured to prevent contamination?

Cleanroom doors are manufactured using precision techniques to minimize seams and gaps that could harbor contaminants. They are engineered to maintain airtight seals, ensuring controlled airflow and pressure differentials.

What certifications do cleanroom doors require?

Cleanroom doors might need to comply with standards such as ISO 14644 for cleanliness levels and other industry-specific regulations. Certifications demonstrate adherence to these standards.

Can cleanroom doors be customized?

Yes, cleanroom doors can be customized to fit the cleanroom's specifications. This includes size variations, window placements, and integration with access control systems.

How are cleanroom doors installed?

Cleanroom doors are installed by experienced technicians who ensure proper alignment, airtight seals, and integration with the cleanroom infrastructure, including airlocks and pass-through chambers.

How do cleanroom doors contribute to operational efficiency?

Cleanroom doors optimize operational efficiency by preventing contamination, maintaining controlled environments, and facilitating smooth personnel and equipment movement.

What maintenance is required for cleanroom doors?

Regular maintenance is essential to ensure cleanroom doors continue to function optimally. This includes cleaning, lubrication, and periodic checks for wear and tear.

Can cleanroom doors be retrofitted into existing cleanrooms?

Yes, cleanroom doors can often be retrofitted into existing facilities with proper planning and installation procedures.

Are there specialized security options for cleanroom doors?

Yes, cleanroom doors can be equipped with access control systems, such as keycards, biometric readers, and interlocking mechanisms, to enhance security.