-

Home / Products

Products

Products Supplier of Aluminum

We specialise in producing aluminium profiles and related industrial frames, semi-finished or assembled products. Cleanroom aluminium profiles, air handling unit (AHU) Frame Profiles, tuyere aluminium profiles and cleanroom doors, medical automatic doors, swing doors, air diffusion (control air doors, water baffles, linear slot diffusers, air grilles) and other products are produced by Our company has. We better control quality and price. Also, you can buy aluminium profiles by meter or kilo. Assemble the product in your factory. Products are widely used in a clean rooms, medical and health, biopharmaceutical, food and beverage, cosmetics, machinery and electronics and other industries.

- Cleanroom door is a specially designed door that is used in cleanroom environments to limit the amount of contamination that can enter or exit the room. These doors are engineered to provide an airtight seal to prevent air leakage, which can allow the infiltration of contaminants from outside the cleanroom environment.

- Cleanroom doors are typically made from materials such as stainless steel, fiberglass, or aluminum. They may also feature specialized seals and gaskets to ensure that no air or dust can pass through the door's cracks and gaps.

- Cleanroom doors may also come equipped with features such as interlocks and electromagnetic locks to ensure that the door remains closed at all times. Interlocks prevent the door from being opened when the cleanroom is in use, while electromagnetic locks provide additional security by preventing unauthorized access to the cleanroom.

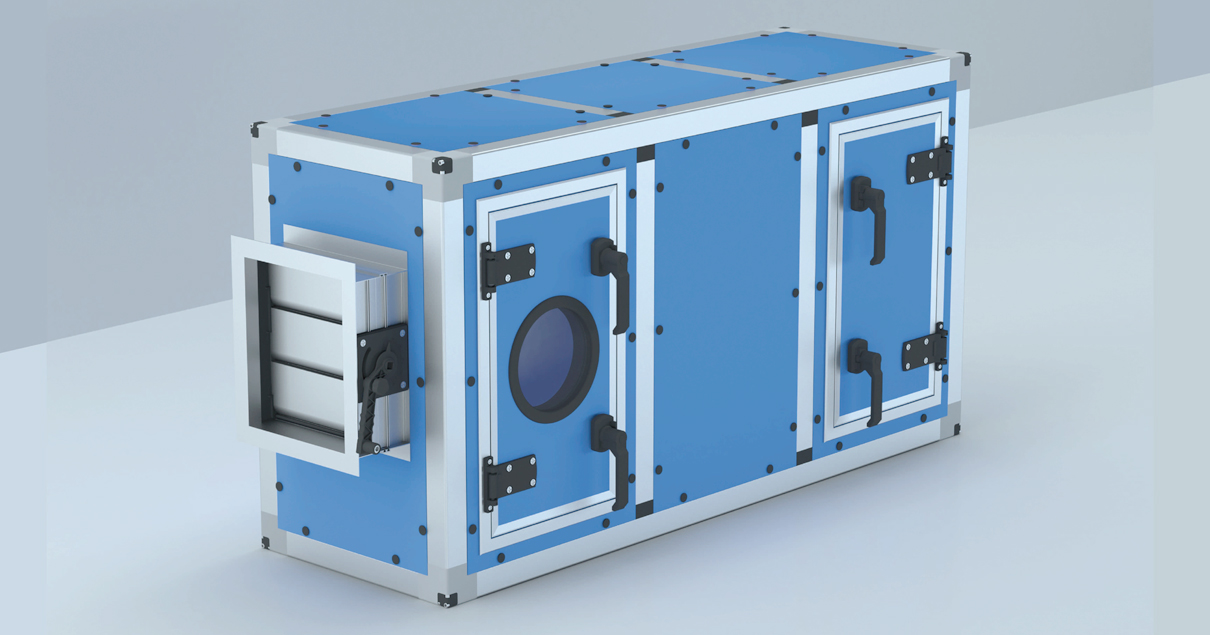

- An AHU (Air Handling Unit) aluminum profile is a type of aluminum extrusion that is specifically designed for use in constructing the framework, casing, and support structures of air handling units. AHU aluminum profiles are made from high-quality aluminum alloy, which provides strength, load-bearing capacity, and resistance to corrosion.

- These profiles are used in constructing the framework of an air handling unit, which allows for easy assembly and installation of the unit. The framework also provides support and protection for the internal components of the AHU, such as the fan, filters, and coil. The AHU aluminum profile construction allows for customized designs, making it easy to adapt the AHU to specific applications and requirements.

- AHU aluminum profiles come in a wide variety of shapes and sizes, and can be easily machined to meet specific structural requirements and tolerances. The profiles may feature integral grooves and slots that enable easy attachment of internal components and accessories. They may also be powder-coated or anodized to enhance their durability and appearance.

- The type of material used: AHU frames can be made of steel, aluminum, or other materials, each of which has its own advantages and disadvantages.

- The thickness of the material: The thickness of the material used in the AHU frame will affect the strength and durability of the unit.

- The shape of the frame: AHU frames may have different shapes and profiles depending on the size and type of unit.

- The size of the frame: AHU frames come in a range of sizes to suit different building and HVAC (heating, ventilation, and air conditioning) system requirements.

- HVAC air diffusers include Square ceiling diffusers, Round ceiling diffusers, Floor diffusers, Wall-mounted diffusers, Disc diffusers, Return diffusers, Linear grille, slot diffusers, swirl diffusers, and jet diffusers, ets. come in different shapes and sizes such as circular, rectangular, or square. They can be made of materials such as aluminum, steel, or plastic to meet specific application requirements.

- Air diffusion refers to the process of dispersing air throughout a space in order to provide ventilation and maintain a comfortable indoor environment. This can be accomplished through the use of HVAC, which are devices that regulate and circulate air in buildings and other enclosed spaces. HVAC typically consist of a fan or blower, heating and cooling elements, and a filter to remove contaminants from the air.

- The air diffuser works by regulating the volume of air flowing through the HVAC system, ensuring that the airflow is evenly distributed into a room. They are equipped with grilles or louvers that help control the direction of the air flow and create a comfortable environment by evenly dispersing the cooled or heated air throughout the space.

There are several different methods of air diffusion that can be used, depending on the specific needs and requirements of the space. These methods include:

- Natural diffusion: This occurs when air flows naturally through open windows or doors, or through openings in the walls or ceiling of a space.

- Forced diffusion: This occurs when air is circulated using mechanical means, such as an HVAC or a ventilation fan.

- Displacement diffusion: This occurs when air is introduced at the floor level and rises up to the ceiling, replacing the warmer, stagnant air that is already present.

- Mixing diffusion: This occurs when air is introduced at multiple points within a space, mixing with the existing air to create a more evenly distributed and comfortable environment.

- Cleanrooms are specialized environments that are designed to maintain a very high level of cleanliness in order to prevent contamination by dust, particulates, and other contaminants. Cleanrooms are used in a variety of industries, including pharmaceuticals, semiconductors, and research and development, where it is critical to maintain a contamination-free environment.

- Cleanroom aluminum profiles are typically designed to meet specific cleanliness standards, such as those set by the International Organization for Standardization (ISO). These standards specify the maximum levels of contaminants that are allowed in the cleanroom environment, as well as the materials and construction methods that must be used to ensure that the cleanroom meets these standards.

- Extrusion that is designed and manufactured specifically for use in cleanroom environments. These profiles are used in cleanroom construction to build frameworks, fixtures, and support structures that are needed to create a clean and sterile operating environment.

- Cleanroom aluminum profiles offer a variety of benefits that make them well-suited for use in cleanroom environments. They are lightweight, yet strong and durable, which allows them to withstand the harsh and rigorous demands of cleanroom operations. They are also resistant to corrosion and easy to clean, ensuring that they can maintain their integrity and sterility even after prolonged use.

- Cleanroom aluminum profiles are available in various shapes and sizes, making them versatile and adaptable to a variety of construction needs. They can be designed with a variety of features, such as T-slots, which allow for modular design configurations, making them easy to integrate with other equipment and systems in the cleanroom. They can also be powder-coated or anodized to provide added protection against wear and tear and to improve their aesthetic appeal.

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.