Stainless Steel Clean Room Doors 2024 — Elevating Cosmetics Manufacturing

- By:hqt

- 2024-03-12

- 29

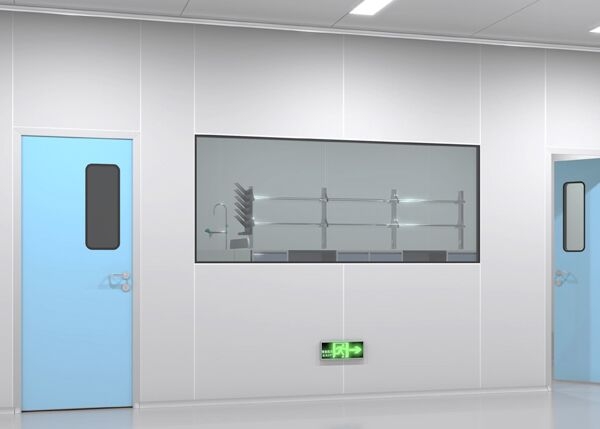

In the realm of cosmetics manufacturing, where stringent cleanliness standards are paramount, the choice of cleanroom equipment plays a crucial role in ensuring both operational efficiency and product quality. Among these essential components, stainless steel clean room doors stand out for their ability to meet rigorous hygiene requirements while offering durability and reliability.

Benefits of Stainless Steel Clean Room Doors

1. Hygiene Maintenance: Stainless steel clean room doors provide an impenetrable barrier against contaminants, preventing the ingress of dust, microbes, and other particulates into sensitive production areas. Their smooth, non-porous surface is easy to clean and disinfect, minimizing the risk of cross-contamination and maintaining the pristine conditions required for cosmetics manufacturing.

2. Durability and Longevity: Unlike traditional doors, which may degrade over time due to exposure to harsh cleaning chemicals or frequent use, stainless steel clean room doors are highly resistant to corrosion, abrasion, and wear. This durability ensures prolonged service life, reducing the need for frequent replacements and associated downtime in production facilities.

3. Operational Efficiency: The seamless integration of stainless steel clean room doors within cleanroom environments enhances workflow efficiency by facilitating smooth ingress and egress of personnel and materials. Their robust construction and reliable sealing mechanisms contribute to maintaining consistent pressure differentials and environmental control, which are essential for preserving product integrity and meeting regulatory standards.

Understanding the Cosmetics Industry Landscape

In recent years, the cosmetics industry has experienced exponential growth driven by evolving consumer preferences, technological advancements, and globalization. With an increasing emphasis on product safety, efficacy, and sustainability, cosmetics manufacturers are under mounting pressure to adhere to stringent quality standards and regulatory requirements.

Importance of Cleanroom Standards

1. Product Quality Assurance: Cleanroom environments play a pivotal role in safeguarding product quality by minimizing the risk of contamination during various stages of cosmetics production, including formulation, filling, and packaging. Maintaining stringent cleanliness standards ensures consistency in product composition, texture, and appearance, enhancing consumer satisfaction and brand reputation.

2. Regulatory Compliance: Regulatory agencies, such as the FDA and EU Cosmetics Regulation, impose strict guidelines on cosmetics manufacturing practices to ensure consumer safety and product efficacy. Compliance with cleanroom standards, including ISO 14644 and GMP (Good Manufacturing Practice), is essential for obtaining regulatory approvals and market access, underscoring the significance of utilizing appropriate cleanroom equipment, such as stainless steel doors.

Identifying Cleanroom Needs and Challenges in Cosmetics Manufacturing

While cleanroom environments are indispensable for ensuring product quality and regulatory compliance in cosmetics manufacturing, they present unique challenges and complexities that necessitate careful consideration and strategic solutions.

Cleanliness Requirements

1. Stringent Contamination Control: Cosmetics production facilities must maintain a pristine environment free from particulate matter, microbial contaminants, and other potential sources of product contamination. Stainless steel clean room doors act as crucial barriers, preventing the infiltration of airborne pollutants and ensuring the integrity of the manufacturing process.

2. Sterility Maintenance: Certain cosmetics, such as sterile formulations or products intended for use around sensitive areas like the eyes, require adherence to stringent sterility protocols. Stainless steel clean room doors with smooth, crevice-free surfaces and hermetic sealing capabilities minimize the risk of microbial ingress, facilitating compliance with sterility requirements.

3. Regulatory Scrutiny and Compliance: Cosmetics manufacturers are subject to rigorous regulatory oversight, necessitating adherence to a myriad of industry standards and guidelines. Failure to comply with cleanroom standards can result in regulatory sanctions, product recalls, and reputational damage, highlighting the imperative of investing in high-quality cleanroom equipment from reputable manufacturers like E-ZONG.

Solutions: The Versatility of Stainless Steel Clean Room Doors

In the dynamic landscape of cosmetics manufacturing, maintaining stringent cleanliness standards is paramount to ensuring product quality and consumer safety. Stainless steel clean room doors emerge as a versatile solution, offering a myriad of benefits tailored to meet the unique needs of cosmetics facilities.

Benefits of Stainless Steel Clean Room Doors

1. Durability: Stainless steel is renowned for its exceptional durability, making it an ideal material choice for clean room doors subjected to rigorous use in high-traffic areas. Unlike traditional doors, which may deteriorate over time due to exposure to harsh cleaning agents or frequent operation, stainless steel doors withstand the test of time, ensuring long-term reliability and performance.

2. Corrosion Resistance: Cosmetics manufacturing environments often involve exposure to moisture, chemicals, and other corrosive substances that can compromise the structural integrity of conventional door materials. Stainless steel clean room doors exhibit inherent corrosion resistance, rendering them impervious to rust, staining, and degradation, even in harsh operating conditions.

3. Customizable Designs: Flexibility is a hallmark of stainless steel clean room doors, with manufacturers like E-ZONG offering customizable designs tailored to meet the specific requirements of cleanroom facilities. From varying sizes and configurations to specialized features such as viewing windows, pass-through ports, or integrated interlocking systems, stainless steel doors can be tailored to seamlessly integrate into diverse cleanroom environments.

Design Ideas: Tailoring Clean Room Doors for Cosmetics Facilities

Innovative design concepts play a pivotal role in optimizing the functionality and performance of stainless steel clean room doors within cosmetics manufacturing facilities. By leveraging advanced engineering principles and ergonomic considerations, designers can develop bespoke solutions that enhance cleanliness, efficiency, and operational safety.

Key Design Features

1. Smooth Surfaces: Ensuring ease of cleaning is paramount in cosmetics manufacturing environments where maintaining pristine hygiene standards is imperative. Stainless steel clean room doors with smooth, crevice-free surfaces minimize the risk of microbial buildup and facilitate effortless sanitation, reducing downtime and enhancing productivity.

2. Air-Tight Seals: Effective containment of airborne contaminants is critical in cleanroom environments to prevent cross-contamination and maintain product integrity. Stainless steel doors equipped with air-tight seals and gaskets provide reliable barrier protection, ensuring optimal cleanliness levels and compliance with regulatory standards.

3. Customizable Sizes: Cleanroom facilities come in various sizes and configurations, necessitating the availability of stainless steel doors in customizable dimensions to accommodate diverse production spaces. Whether it's a small-scale laboratory setting or a large-scale manufacturing facility, E-ZONG offers tailored solutions designed to fit seamlessly into any cleanroom layout while maximizing usable space.

Trends Shaping the Future of Cleanroom Technology in Cosmetics

As the cosmetics industry continues to evolve, driven by advancements in technology, consumer preferences, and sustainability initiatives, cleanroom technology undergoes a transformation to meet the evolving needs of cosmetics manufacturers. Emerging trends in cleanroom door design reflect a convergence of innovation, efficiency, and environmental consciousness.

Advancements in Cleanroom Door Technology

1. Smart Sensors: Integration of smart sensor technology enables real-time monitoring of environmental parameters such as temperature, humidity, and air quality, enhancing control and traceability within cleanroom facilities. Stainless steel clean room doors equipped with intelligent sensor systems offer proactive alerts and insights, facilitating predictive maintenance and operational optimization.

2. Automation: Automation plays a pivotal role in streamlining cleanroom operations, minimizing human intervention, and reducing the risk of contamination. Automated stainless steel clean room doors featuring motorized opening mechanisms, touchless entry systems, and programmable access controls enhance workflow efficiency while ensuring adherence to strict cleanliness protocols.

3. Sustainable Materials: With a growing emphasis on sustainability and eco-friendly practices, cosmetics manufacturers are increasingly turning to cleanroom door solutions crafted from sustainable materials such as recycled stainless steel or bio-based polymers. E-ZONG's commitment to environmental stewardship is reflected in its innovative use of sustainable materials, contributing to the industry's transition towards greener, more responsible manufacturing practices.

Conclusion

Stainless steel clean room doors play a pivotal role in enhancing efficiency, maintaining hygiene, and ensuring regulatory compliance within cosmetics manufacturing facilities. By understanding the unique cleanliness requirements and challenges inherent in the cosmetics industry, manufacturers can make informed decisions regarding the selection and implementation of cleanroom solutions to safeguard product quality and consumer safety.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution

Next-Gen Medical Cleanroom Access: Introducing the Cleanroom Steel Door Solution -

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow

Linear Bar Grille Air Conditioning Diffuser with 0° Angle Blades for Perfect Airflow -

The Sleek and Efficient Linear Slot Diffuser for Air Vent

The Sleek and Efficient Linear Slot Diffuser for Air Vent -

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors

Double-Swing Glass Doors - Modern Laboratory Cleanroom Doors -

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door

Superior Aluminium Glass Swing Door - Pharmaceutical Cleanroom Door -

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency

E-ZONG Leads the Way in China's Medical Lead Protection Doors: Innovation for Safety and Efficiency -

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces

E-ZONG: Leading the Suppliers of Glass Airtight Automatic Doors for Safer, Cleaner Spaces -

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent

How Wall Air-Tight Swing Doors Ensure Clean Environments With Secure & Silent -

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions

Seamless Automatic Cleanroom Sliding Doors: Smooth, Safe, and Hygienic Solutions -

Elegant & Durable: Premium Swing Door Protection for Hospitals

Elegant & Durable: Premium Swing Door Protection for Hospitals

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind