What is a Cleanroom? Everything You Need to Know

- By:hqt

- 2024-11-25

- 29

Have you ever wondered how pharmaceutical drugs are manufactured in an environment free of contaminants? Or how semiconductor chips are fabricated with precision down to microscopic details? The answer to these questions lies in the cleanroom — a critical component in industries where precision, hygiene, and the utmost cleanliness are non-negotiable. But what exactly is a cleanroom, and why is it so vital?

What is a Cleanroom? In this blog, we’ll delve into the fascinating world of clean rooms, exploring their uses, components such as clean room doors and aluminum profiles. And learn why they are critical in industries such as healthcare, pharmaceuticals and research.

What is a Cleanroom?

What is a Cleanroom? A cleanroom is a highly controlled environment. It is designed to keep contaminants such as dust, airborne microorganisms, aerosol particles, and chemical vapors at extremely low levels. These rooms are specially constructed to ensure that specific cleanliness standards are met. These standards are often set by organizations such as the International Organization for Standardization (ISO). In industries where even the tiniest contamination can result in significant product defects or health risks, cleanrooms are indispensable.

Cleanrooms serve various sectors, from pharmaceuticals, where contamination can affect drug purity, to electronics, where a single speck of dust can ruin microchips. These specialized environments operate by tightly controlling air quality, humidity, pressure, and airflow to achieve stringent cleanliness requirements.

Cleanroom Doors: The Gateway to Cleanliness

What Makes a Cleanroom Door Special?

Cleanroom doors are not your typical doors. They play a critical role in maintaining the cleanroom’s integrity by limiting contamination from the outside world. A cleanroom door is engineered to provide an airtight seal that prevents any exchange of air, particles, or contaminants. The purpose of these doors is not only to act as an entry point but also to reinforce the clean environment inside the room, where every particle counts.

To ensure absolute sealing, cleanroom doors are designed with specialized seals and gaskets that eliminate the possibility of leaks. This airtight barrier keeps contaminants out, allowing the cleanroom’s complex filtration systems to maintain a pristine environment.

Types of Cleanroom Doors

Cleanroom doors can be made of various materials such as:

Steel Doors: Offering durability and a reliable seal.

High-Pressure Laminate (HPL) Doors: Resistant to chemical wear and frequent cleaning.

Galvanized Steel Doors: Corrosion-resistant, making them suitable for long-term use.

Glass Doors: Allows for visibility while maintaining a tight seal.

Aluminum Frame Doors: Lightweight but strong, providing easy installation and efficient sealing.

Automatic Sliding Doors and Manual Swing Doors: Depending on the cleanroom’s requirements, these doors can be either manually or automatically operated to suit different scenarios.

These doors are versatile and can be used in various critical areas of a cleanroom. These include entrances, isolation rooms, operating rooms, ICU units, and even emergency exits.

Key Features of Cleanroom Doors

Cleanroom doors come with advanced features to maintain cleanliness:

Airtight Seals: Ensuring that no air or dust particles enter or exit.

Interlocks and Electromagnetic Locks: These systems keep the door securely shut, minimizing the risk of accidental contamination. Interlocks prevent the door from opening while the cleanroom is active, while electromagnetic locks help control unauthorized access.

Durable Materials: Stainless steel, fiberglass, and aluminum are commonly used due to their resistance to corrosion and ease of cleaning.

When choosing the best cleanroom door, E-ZONG provides complete solutions for various materials tailored to all corners of cleanrooms, including specialized areas in hospitals.

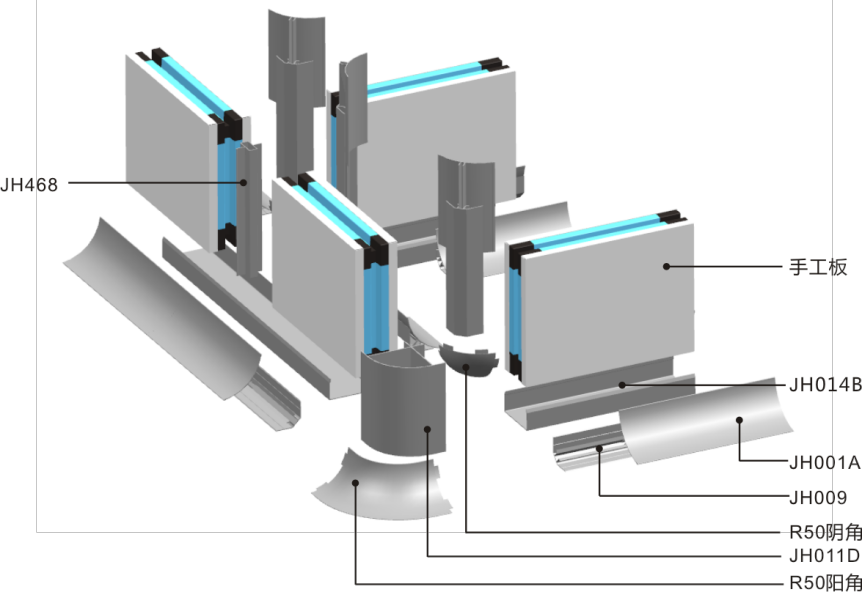

Cleanroom Aluminium Profiles: The Backbone of Cleanroom Construction

The Role of Aluminium Profiles in Cleanrooms

Cleanroom aluminium profiles are essential structural elements that support the modular construction of cleanroom wall panels and systems. These profiles serve as the backbone, providing the necessary framework to build fixtures, support structures, and integrate different cleanroom components seamlessly.

Cleanroom aluminium profiles are designed with precision and manufactured to meet stringent cleanliness standards. They are used to build durable frames. They help maintain the sterile conditions necessary for operations in industries such as pharmaceuticals, electronics and healthcare.

Benefits of Cleanroom Aluminium Profiles

Strength Without Weight: Aluminium profiles are lightweight but incredibly strong, allowing for easy installation without compromising on the strength needed to support the cleanroom infrastructure.

Corrosion Resistance: Aluminium naturally resists corrosion, which is crucial in environments where frequent cleaning and exposure to chemicals are common.

Versatility: Available in different shapes and sizes, aluminium profiles can be designed to include T-slots, which allow for modular design configurations. This versatility makes it easy to integrate these profiles with other cleanroom elements like doors, panels, and windows.

Aesthetic and Functional Finishes: Aluminum profiles can be powder coated or anodized. This adds an extra layer of protection and an aesthetically pleasing surface, which is crucial in environments where aesthetics and cleanliness are closely related.

Clean room aluminum profiles not only increase the structural integrity of the clean room. It also allows for design flexibility, offering modular construction options that can adapt to changing industry needs.

Why Are Cleanrooms So Critical?

Maintaining Sterility in Healthcare

In healthcare, cleanrooms are essential to maintaining a sterile environment where critical tasks like surgeries, drug preparation, and sample testing occur. Any form of contamination could have life-threatening consequences. Hospital cleanrooms must adhere to the highest cleanliness standards. This is achieved through controlled environments, advanced filtration systems, and equipment such as cleanroom doors and aluminum profiles that completely seal the space.

Precision in Pharmaceuticals

Cleanrooms are also indispensable in the pharmaceutical industry. The production of medicines requires environments free from dust, particulates, and airborne microbes. Any contamination can compromise drug efficacy and safety, which is why pharmaceutical manufacturing is carried out in strictly controlled cleanroom settings.

Microchip Manufacturing and Contamination Control

The semiconductor industry relies on cleanrooms because manufacturing microchips requires an extremely clean environment. Even a single dust particle can render an entire chip useless. Thus, cleanrooms used in semiconductor fabrication are often of the highest cleanliness class, ensuring that the chips produced are defect-free and high quality.

The Importance of Cleanroom Suppliers

Creating and maintaining a cleanroom requires specialized equipment, expertise, and dedication. The best cleanroom doors, cleanroom wall panels, and aluminium profiles all come together to create an environment that meets the strict cleanliness requirements of sensitive industries.

E-ZONG is a leader in providing cleanroom solutions, offering cleanroom doors and aluminium profiles that meet industry standards and provide peace of mind in critical environments. From durable galvanized steel doors to flexible aluminum frames. E-ZONG's products are designed to ensure your cleanroom remains contamination-free.

Conclusion: Cleanrooms are More Than Just Spaces

Cleanrooms are complex environments engineered with one goal in mind — to prevent contamination. From special clean room doors to aluminum profiles for supporting structures. Every component is carefully designed to ensure cleanliness standards are met. Without these critical components, industries such as pharmaceuticals, healthcare, and semiconductor manufacturing would struggle to maintain the integrity of their products and services.

Whether you are constructing a new cleanroom or looking to improve an existing one, choosing the right materials and partners is crucial. Companies like E-ZONG provide cleanroom solutions that ensure reliability, safety, and top-notch quality in maintaining contamination-free environments.

Cleanrooms may often go unnoticed, but they are at the heart of critical industries. Ensuring we get safe medicines, high-quality electronics, and reliable healthcare. The next time you take a life-saving medication or power up your smartphone, spare a thought for the cleanroom – the invisible heroes behind the scenes making sure everything works as it should.

We hope this blog gave you a comprehensive understanding of what cleanrooms are and why they matter. If you're interested in learning more about cleanroom solutions or need assistance with cleanroom doors and aluminum profiles, reach out to E-ZONG for industry-leading expertise and products.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

How to Extend the Life of Your Exterior Steel Door

How to Extend the Life of Your Exterior Steel Door -

What Are the Best Materials for AC Vent Covers

What Are the Best Materials for AC Vent Covers -

Ceiling Vent Covers Labeled Fire-Rated? Here’s How to Verify

Ceiling Vent Covers Labeled Fire-Rated? Here’s How to Verify -

Upgrading Lab Doors: When to Replace vs. When to Retrofit?

Upgrading Lab Doors: When to Replace vs. When to Retrofit? -

Stainless Steel Door vs. Alternatives in Cleanrooms

Stainless Steel Door vs. Alternatives in Cleanrooms -

Ceiling Vent Care Tips to Boost HVAC Efficiency Year Round

Ceiling Vent Care Tips to Boost HVAC Efficiency Year Round -

How Air Dampers Drive Efficiency in High Performance Buildings

How Air Dampers Drive Efficiency in High Performance Buildings -

Why Semiconductor Manufacturing Can’t Function Without Cleanrooms

Why Semiconductor Manufacturing Can’t Function Without Cleanrooms -

How to Select the Right Floor Vent for Cleanrooms

How to Select the Right Floor Vent for Cleanrooms -

How to Clean and Maintain AC Registers for Peak HVAC Performance

How to Clean and Maintain AC Registers for Peak HVAC Performance

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind